Open house event at Shape to mark 5th birthday

Visitors saw what the company refers to as the world’s first VarioFil R+ bottle-to-POY spinning line in operation.

28th January 2015

Innovation in Textiles

|

Remscheid

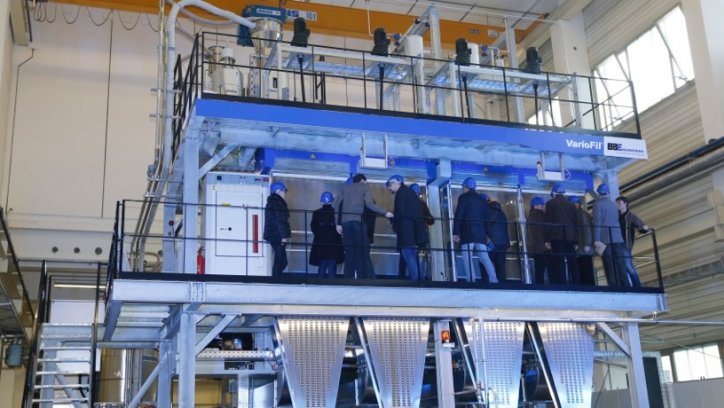

More than 120 customers from around the world followed BB Engineering’s (BBE) invitation to join the unveiling of its new machine during an Open House event at its facilities in Remscheid, Germany, last week.

Visitors saw what the company refers to as the world’s first VarioFil R+ bottle-to-POY spinning line in operation, producing 150f48 dope-dyed black yarn.

The new VarioFil R+ is the POY spinning line, which uses recycled bottle flakes as feedstock for dope-dyed textile POY.

The line, developed by the subsidiary company of Oerlikon Barmag, provides several technological features, such as a special extrusion system for bottle flake materials, the latest metering and blending technology for dope-dyeing, and an advanced 2-step melt filtration.

The result is a high quality dope-dyed POY, according to the manufacturer. The turnkey machine comprises 4 spinning positions, each equipped with an Oerlikon Barmag 10-end WINGS POY winder.

PET has become the primary material for beverage packaging – billions of PET bottles are used worldwide each year. This huge quantity of PET bottles, usually disposed as waste after initial use, is a perfect source of raw material for the sustainable production of synthetic fibres. The reutilization of resources and raw materials, along with energy saving production processes, are becoming increasingly popular.

The VarioFil R+ concept is said to combine all these trends. It uses PET bottle flakes as a raw material, which avoids the additional pelletizing of bottle flakes into rPET chips. This leads to a significant advantage in terms of investment and energy costs. It is also said to provide the latest technology for dope-dyeing, which is the most resource-saving dyeing process.

Hence, the development of VarioFil R+ underlines the trend of increasing demand for textiles made from yarns which have a sustainable background, the company reports. It also provides the possibility for recycling companies to sell high-quality yarns instead of bottle flakes, therefore generating added value.

Further Open House attractions were the live presentation of the texturizing process, converting the manufactured rPOY into DTY on Oerlikon Barmag’s eAFK texturizing machine, as well as BBE’s brand-new cleaning system for melt filters, known as White Filter Cleaning WFC.

WFC allows the cleaning of melt filters, but also of other melt-contaminated parts without any chemical solvents and is a good complementary system for the VarioFil R+ line to clean its filtration equipment.

A virtual tour through the new VarioFil R+ line as well as an impressive insight into the winder assembly department of Oerlikon Barmag, the origin of the famous WINGS POY winder, and several technical presentations covering the fields of recycling, yarn production from recycled feedstock and dope-dyeing all made the Open House an informative day for all participants.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more