Kansai University and Teijin develop piezoelectric wearable sensors

Kansai University and Teijin will introduce the new piezoelectric fabric at The 1st Wearable Expo, the leading wearable devices and products exhibition.

15th January 2015

Innovation in Textiles

|

Tokyo

Prof Yoshiro Tajitsu, Faculty of Engineering Science at Kansai University, and Teijin have developed what they believe to be the world’s first polylactic acid (PLA) fibre and carbon fibre based piezoelectric fabrics.

Kansai University and Teijin will introduce the new piezoelectric fabric at The 1st Wearable Expo, the leading wearable devices and products exhibition, which takes place at the Tokyo International Exhibition Hall in Japan from 14-16 January.

The new piezoelectric fabrics combine Teijin’s polymer and textile technologies with Prof Tajitsu’s knowledge of piezoelectric materials. Development was supervised by Prof Tajitsu at Kansai University, with technological cooperation provided by the Industrial Technology Center of Fukui Prefecture.

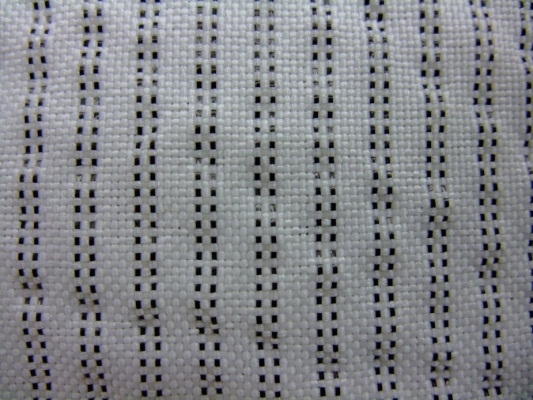

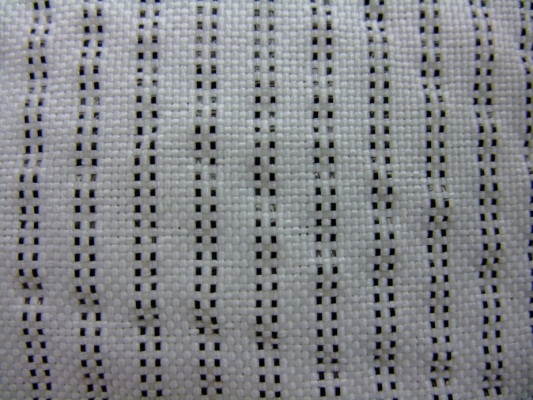

The fabrics comprise a piezoelectric poly-L-lactic acid (PLLA) and carbon fibre electrode. Plain, twill and satin weave versions were produced for different applications: plain weave detects bending, satin weave detects twisting, and twill weave detects shear and three-dimensional motion, as well as bending and twisting.

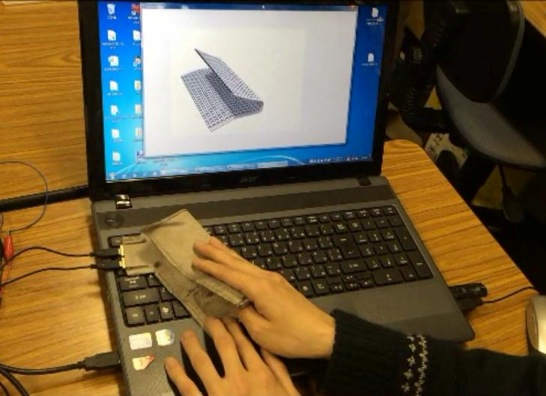

The sensing function, which can detect arbitrary displacement or directional changes, incorporates Teijin’s weaving and knitting technologies. The function is said to allow the fabric to be applied to the actuator or sensor to detect complicated movements, even three-dimensional movements.

Kansai University and Teijin will continue working on ideal weaves and knits for fabric applications that enable elaborate human actions to be monitored simply via clothing worn by people.

Such applications are expected to contribute to the evolution of the Internet of Things (IoT) in fields ranging from elderly care to surgery, artisanal techniques to space exploration, and many others.

Piezoelectricity is the ability of certain dielectric materials to generate an electric charge in response to mechanical stress. It also has the opposite effect – the application of electric voltage produces mechanical strain in the materials. Both of these effects can be measured, making piezoelectric materials effective for both sensors and actuators.

Lead zirconate titanate (PZT) has practical piezoelectric applications in the industry, but as a ceramic material it lacks transparency and flexibility, the company reports. In addition, because PZT contains lead, applications are being increasingly limited by the EU directive that restricts the use of certain hazardous substances in electrical and electronic equipment.

Polyvinylidene fluoride (PVDF) is a well-known piezoelectric polymer. However, it is limited to use in sensors and such, and it is not suited to industrial-level manufacturing because it requires poling treatment and exhibits pyroelectricity. Poling treatment, which involves applying high DC voltage to a material, is a required process for achieving piezoelectricity.

Pyroelectricity is the ability of certain materials to generate a voltage and charge following a change in temperature. The existence of pyroelectricity is a very important factor in human-machine interface (HMI) applications because if a piezoelectric sensor material has pyroelectricity, then it can immediately detect heat from a finger.

In 2012, Kansai University and Teijin developed a flexible, transparent piezoelectric film by alternately laminating PLLA and optical isomer poly-D-lactic acid (PDLA). The all-new wearable piezoelectric fabric is the newest application of this technology.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more