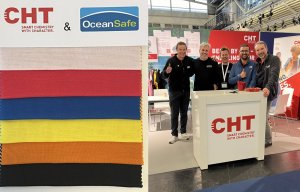

OceanSafe teams up with CHT

Jana Bukolovska spoke to Renee Henze, Marketing Director, DuPont Biomaterials and Sorona, about the benefits of the new development.

-612x408-boxed.jpg)

1st August 2017

Innovation in Textiles

|

Wilmington, DE

DuPont’s Sorona team led a session on its comfort stretch fibre, as a replacement for Spandex, at the recent Outdoor Retailer Summer Market, which concluded last week in Salt Lake City, UT. Renee Henze, Marketing Director, DuPont Biomaterials and Sorona, stressed that stretch is an important attribute in multiple apparel applications, including performance sportswear, work wear and more casual athleisure clothing.

DuPont’s Sorona team led a session on its comfort stretch fibre, as a replacement for Spandex, at the recent Outdoor Retailer Summer Market, which concluded last week in Salt Lake City, UT. Renee Henze, Marketing Director, DuPont Biomaterials and Sorona, stressed that stretch is an important attribute in multiple apparel applications, including performance sportswear, work wear and more casual athleisure clothing.

Although the stretch requirements for most applications can be met with polyurethane fibres, Sorona Stretch Fibre offers a superior solution for its manufacturing, stretch recovery and colour fastness, she says.

DuPont also presented its latest innovation – Apexa biodegradable polyester fibre and Jana Bukolovska spoke to Renee Henze about the benefits of the new development.

Tell us more about DuPont’s latest innovation – Apexa fibre. How does it decompose?

Renee Henze: DuPont Apexa® is a biodegradable polyester that decomposes through industrial composting without creating harm to the soil or environment. Developed through patented and innovative technology, DuPont Apexa® fibre breaks down into simple CO2 and H2O to reduce textile waste and limit environmental impact. In addition to minimizing textile waste, it also blends with natural fibres such as wool, cotton or cellulose to enhance their attributes, making them stronger, softer and more durable.

What other mechanisms to limit impact on the environment are at the company’s disposal?

RH: In addition to Apexa®, DuPont is pioneering bio-based fibres to lessen environmental impact at the onset of a product’s lifecycle with its sustainable polymer Sorona®. Sorona® contains 37% annually renewable plant-based ingredients, using less energy and emitting fewer greenhouse gases during production as compared to other petroleum-based products. It also offers unique performance benefits across applications, including durability, superior softness, excellent stretch recovery, breathability and moisture wicking. Apparel mills, manufacturers and designers that use Sorona® can responsibly source materials and minimize environmental consequences without sacrificing quality and performance.

How important is it to focus of reducing textile waste at both ends of a product’s life?

RH: Sustainable textile sourcing is becoming more important across the entire supply chain, particularly as the apparel industry remains a key contributor to waste and pollution. Environmentally unfriendly consumer habits, including the rise of fast fashion and a growing throwaway culture, further fuel negative ecological impact. According to a 2009 United States Environmental Protection Agency study on municipal solid waste, textile waste has nearly doubled in the past two decades, accounting for about 21 billion pounds per year and 5% of all municipal waste generated in the United States.

The need for a more thoughtful and responsible approach to sourcing textiles and reducing environmental impact is apparent – from manufacturing and design, to sale and end use. Through Sorona®, Apexa® and the exploration of additional fibre advancements, DuPont is committed to driving innovation that make positive contributions to the textile industry.

What are the main objectives of the new Sorona Common Thread corporate social responsibility programme?

RH: Through both its bio-based product and its conscious business values, Sorona® is focused on driving social and environmental change. With its new environmental and social responsibility program, The Common Thread, Sorona® aims to collaborate with key brand partners on their existing philanthropic efforts by participating in partner events and contributing to their CSR initiatives. Programs may range from recycled clothing programs to environmental clean-up events to community action initiatives. With The Common Thread, Sorona® is not only promoting environmental and social good, but also supporting its partners in their mission to empower change.

Sorona is currently collaborating with other fibre brands like Lenzing and Toray Primeflex. What are the results of those collaborations?

RH: Sorona® blended with Lenzing’s Tencel elevates the attributes of the individual fibres, creating a soft, lightweight and absorbent fabric. Toray Primeflex incorporates a blend of Sorona® creating a lightweight, windproof, four-way stretch woven that offers supreme flexibility, comfort and stretch recovery.

.jpg)

The Sorona team led a session on its comfort stretch fibre, as a replacement for Spandex, at the recent Outdoor Retailer. How do you justify this claim?

RH: Stretch is an important attribute in multiple apparel applications, including performance sportswear, work wear and more casual athleisure clothing. Although the stretch requirements for most applications can be met with polyurethane fibres, such as Spandex invented by DuPont in the 1950s, or the Sorona® Stretch Fibre, the Sorona® Stretch Fibre offers a superior solution for its manufacturing, stretch recovery and colour fastness. Unlike polyurethane fibres, Sorona® Stretch Fibres do not need to be covered during the spinning process, reducing time, complexity and cost for fabric manufacturers. Additionally, polyurethane fibres lose their stretch and stretch recovery over time after repeated use or washes and exposure to heat and common chemicals like chlorine and sunblock ingredients; Sorona® Stretch Fibres are not affected by these agents and therefore maintain excellent stretch recovery over time. Sorona® Stretch Fibres also show outstanding colour fastness, in comparison to dyes in polyurethane fibres.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more