Textile machinery for a sustainable textiles industry

According to Germany’s VDMA Textile Machinery Association, the forthcoming ITMA ASIA + CITME in Shanghai is an excellent platform for German technology suppliers who will play a key role in the technological upgrading of the Chinese textiles industry.

27th April 2012

Innovation in Textiles

|

Frankfurt

According to Germany’s VDMA Textile Machinery Association, the forthcoming ITMA ASIA + CITME in Shanghai is an excellent platform for German technology suppliers who will play a key role in the technological upgrading of the Chinese textiles industry.

According to Germany’s VDMA Textile Machinery Association, the forthcoming ITMA ASIA + CITME in Shanghai is an excellent platform for German technology suppliers who will play a key role in the technological upgrading of the Chinese textiles industry.

The VDMA says efficient textile production will be the main topic at June’s ITMA ASIA + CITME 2012 in Shanghai, especially as government regulations aiming at higher energy efficiency have been passed in both China and India.

Adjusting to volatile energy and commodity prices as well as ecological requirements from retailers and consumers are also presenting a challenge for textile producers throughout Asia and the VDMA says its member companies are well positioned to give visitors to ITMA ASIA ‘profound answers’ on how to increase energy or material efficiency and so combat cost pressure whilst fulfilling the needs of the market.

China’s textile industry has entered a new era and countries like India, Bangladesh or Vietnam are leveraging cost advantages to compete with China for international markets. Apart from external factors, China’s latest Five-Year Plan is also aiming high with ambitious goals.

“The Chinese textile industry is facing a transformation process in the years ahead. The 12th Five-Year Plan sets ambitious goals. Sophisticated textile products for high-end markets, enhanced productivity, energy savings and emission reductions are just some key words that describe the tasks for the Chinese textile sector. All this requires technological upgradation” explains Fritz P. Mayer, Managing Associate of Karl Mayer and Chairman of the VDMA Textile Machinery Association.

“The German technology suppliers can play a major role to reach the targets in the upcoming change process of the Chinese textile industry. ITMA ASIA 2012 provides an excellent platform for the German textile machinery companies to demonstrate, how their products and services can help the Chinese textile sector to evolve into a modern high tech industry,” Mayer adds.

Blue Competence

Blue CompetenceNew technical solutions are increasingly considered with regard to their economic and ecological efficiency. But, the VDMA says, for textile producers it is not easy to get orientation, because the whole discussion about efficiency criteria and comparability is sometimes far from being objective.

With this in mind VDMA will present the sustainability initiative Blue Competence for the first time in the Asian market at the Shanghai exhibition. The initiative explains and positions the machinery manufacturers as the technical problem-solvers regarding the requirements of the society of today and of the future in saving energy, material and resources.

The VDMA will distributing information and showcasing technologies and products produced by its members during the exhibition.

“Within the framework of the Blue Competence initiative, VDMA member companies provide well founded answers for instance to the topic energy efficiency. At ITMA ASIA, the VDMA energy efficiency guide Conserving resources – securing savings-potential will be distributed in Chinese language. In the guide the determining factors for comparative assessment of the energy efficiency of textile machinery has been worked out,” the VMA explains.

“Some activities in the market in the last time regarding criteria and comparability were not very well founded, because they tried to measure complex textile machinery like consumer electronics or household appliances. The VDMA guide shall help to put the discussion about energy efficiency on a solid basis again.”

The guide will be available at the VDMA booth and at the booths of more than 20 VDMA member companies.

In the run-up to and during the show, the VDMA will publish best practice examples from VDMA member companies. The success stories themed Sustainability meets profit will include examples of sustainable machines and components as well as sustainable textile products that have been manufactured with the help of machines from VDMA members.

112 German companies have registered for ITMA ASIA 2012 which is an increase of 9 % compared to the 2010 show.

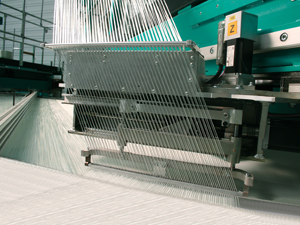

“All the renowned German manufacturers will be present at the leading trade fair for the Asian market. The German exhibitors will cover almost all different machinery chapters with a strong focus on spinning, finishing, knitting, nonwovens, weaving and winding technology,” the VDMA says.

“For visitors it will be easy and convenient to find and visit German exhibitors as most of them will use Made in Germany and German Technology logos. Furthermore, VDMA has initiated German sector groups in hall E2 (finishing), E5 (knitting & braiding) and W2 (spinning).”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more