Bally Ribbon Mills at IFAI 2018

E-Webbings are specially designed for use in a wide range of integral and wearable products.

20th November 2019

Innovation in Textiles

|

Bally, PA

Bally Ribbon Mills’ E-Webbings. © BRM

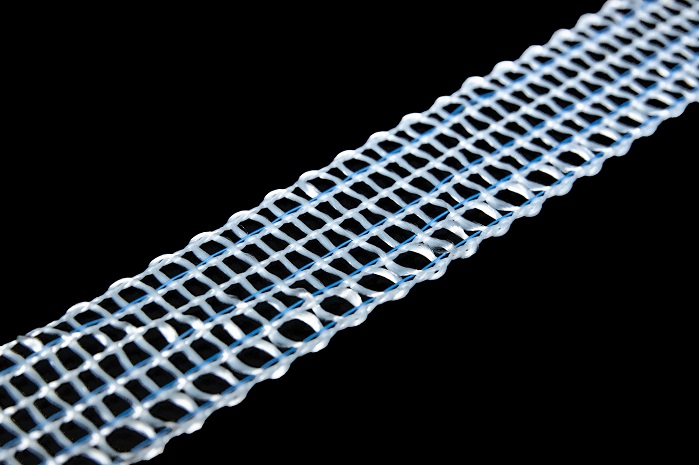

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialised engineered woven fabrics, has announced its proprietary E-Webbings e-textile product base, specifically designed to serve as a customisable base for a wide range of smart textile applications within the Internet of Things (IoT).

“These smart textiles serve as the foundation layer to which electronic intercommunicative technology is integrated directly. They allow for smaller final product size, lower weight, optimal user comfort, and significant cost savings,” the company explains.

E-Webbings are specially designed for use in a wide range of integral and wearable products. © BRM

E-Webbings narrow woven fabrics are made from a wide variety of fibres and conductive elements that allow electronics and digital parts to be embedded in them. BRM works with customers to design the structural and conductive components that allow for the detection and gathering of data depending on the specific applications.

Before beginning work on designing and customizing E-Webbings, BRM engineers take the time to understand the purpose and specific requirements of the end device and work closely with clients throughout each step of the process to ensure all needs are met, the company says.

E-Webbings narrow woven fabrics are made from a wide variety of fibres. © BRM

Designers select each component and factor that goes into an E-Webbings textile, so the conductor, base webbing, power source, and sensor work seamlessly together. Conductive fibres or wires can be woven right into the E-Webbings fabric, allowing for transmission of power and information without the need for additional wiring in the final component.

BRM also offers many sensor options, based on where within the product the textile structure is located, and what types of information and data it needs to measure.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more