Chargeurs partners with CLO in 3D digital design process

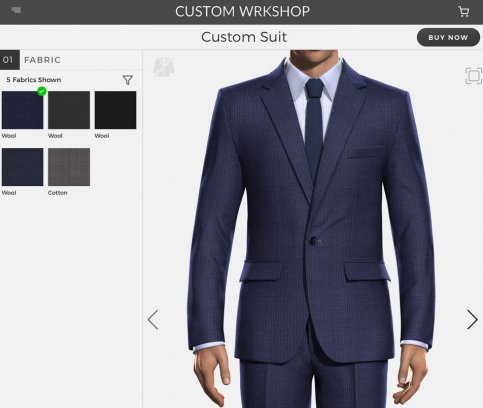

Custom Wrkshop enables made-to-order fashion manufacturing.

11th October 2021

Innovation in Textiles

|

New York

Chargeurs PCC Fashion Technologies, the New York-headquartered apparel interlinings manufacturer, is partnering with Custom Wrkshop, an on-demand platform for customisation and made-to-order apparel, shoes and accessories.

As the exclusive supplier of sustainable interlinings and inner components to Custom Wrkshop’s network of customers, Chargeurs will also present the online platform as a service to its own global network of more than 6,000 customers and partners.

Custom Wrkshop provides front and back-end digitisation tools that enable consumers to customise garments and receive them directly from manufacturers in about two weeks. By partnering with it, Chargeurs is building on its early sustainability investments and cementing its leadership as a full-circle digital company driving sustainability and flexibility at every stage of production, from design, development and manufacturing to marketing and selling.

Eliminating waste

“Made-to-order manufacturing is one of the most sustainable options available to the fashion industry and consumers, as it eliminates materials waste, overproduction and costly returns due to poor fit,” said Audrey Petit, managing director of Chargeurs PCC Fashion Technologies. “We’re happy to partner with Custom Wrkshop to supply our sustainable interlinings and inner components to its customers and enable conscious manufacturing through its global network of fully digitised factory partners. In addition, we will be offering Custom Wrkshop’s plug-and-play software to our own customers, allowing them to easily add a module connected to digitised manufacturing facilities to their e-commerce stores so their end customers can create made-to-order pieces.”

The Custom Wrkshop platform provides brands with back-end connections to digitised manufacturing facilities across the globe, helping solve overproduction and inventory shipping challenges. For designers of garments, footwear, bags and accessories, its real-time costing engine provides full visibility into cost during the design process, reducing the use of materials while boosting speed to market. Chargeurs launched an exclusive partnership with 3D design software leader CLO last year and brand designers can now easily import digital assets created with CLO into the Custom Wrkshop platform.

In 2019, Chargeurs launched the apparel industry’s first complete collection of interlinings and inner components made with eco-responsible materials. This Sustainable 360 range is used by leading global brands including Adidas, Itochu, J.Crew, Macy’s, Madewell, PVH, Target and Uniqlo.

The company’s partnership with CLO allows designers to access interlinings as digital assets, giving creators real-time visibility into how a garment’s drape and silhouette will change a design. This information greatly reduces the need for physical samples, preventing waste and unnecessary transportation of goods, while increasing speed to market. In addition, Chargeurs has created a digital showroom that offers an immersive virtual experience for the company’s customers and features a gallery of products for multiple fashion, apparel and accessories categories.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more