Electro-osmosis the key to improved moisture transport

Turkish customers confirm higher output and lower energy consumption.

30th July 2024

Innovation in Textiles

|

Bursa, Turkey

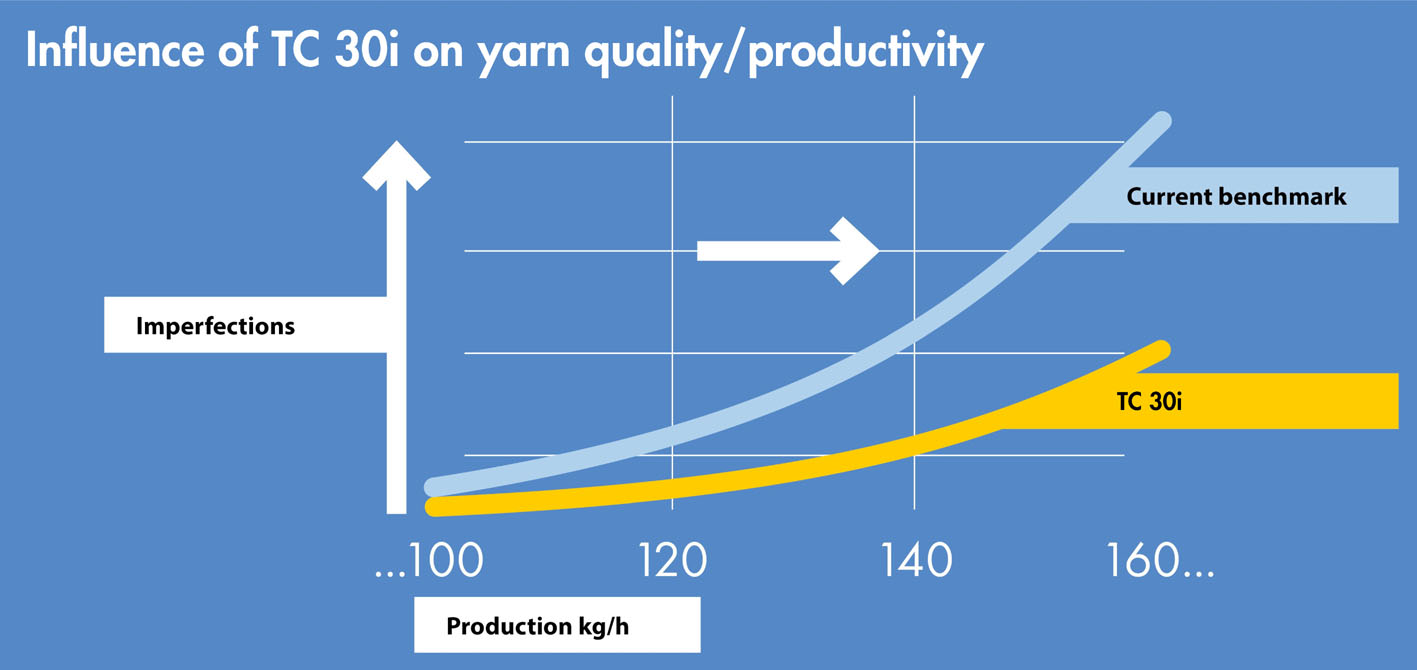

Mayfil Tekstil is a Turkish specialist in textured yarns headquartered in Nilüfer, Bursa. Founded in 2005, the company has grown rapidly and in 2022 invested in a modern vortex airjet spinning facility that can produce up to 35 tons per day. In February this year, Mayfil conducted tests with its TC 30i that produced 140 kg of viscose per hour – more than 40 % higher than the 95 kg/h it previously achieved.

The new carding machine also reduced electricity consumption by 18 % and based on these results, Mayfil is purchasing further TC 30i cards.

Similar results were also achieved by another customer, Göl Iplik Şeremet Tekstil, located in Inegöl, Bursa, which will include the new card in its future investment strategy.

The key benefits of the TC 30i are its high levels of productivity and yarn quality thanks to 35% more active flats, the longest carding length on the market and the T-GO automatic carding gap optimiser.

Consistent results are also achieved without relying on manual operators thanks to automatic, real-time optimisation of the T-GO carding gap, and an advanced waste suction system collects and separates different types of waste, enabling more than 50% of it to be reused or sold to third parties.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more