Monforts to debut its texCOAT coating range at Techtextil 2017

The new range of Monforts coating solutions follows the recent takeover of know-how by Monforts of European coating specialist Timatec.

3rd February 2016

Innovation in Textiles

|

Moenchengladbach

A.Monforts Textilmaschinen, the leading dyeing, finishing and compressive shrinking machine manufacturer, will be demonstrating its latest range of advanced coating machines, including magnetic roller coatings, at the JEC World exhibition that takes place from 28-10 March in Paris.

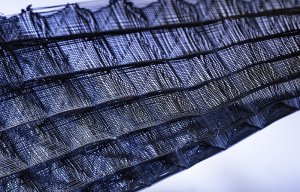

The new range of Monforts coating solutions follows the recent takeover of know-how by Monforts of European coating specialist Timatec. The company has a portfolio of coating units for virtually all applications – including solvents treatment and for wider width fabrics.

Responding to the demand by the coating segment for composites and textile finishing, A.Monforts Textilmaschinen will be demonstrating its coating range as a single source for new and innovative one-stop solutions.

Single sourced solutions including sophisticated lightweight construction using innovative textile-based coated materials in the automotive and aerospace industries will be highlighted.

Technical textiles and coated textiles make high demands on the manufacturer's flexibility. The textile machine must also be flexibly adaptable to precisely these demands. Here Monforts offers tailor-made solutions from a single source.

The various coating modules can be employed with and without magnet system. For working widths over 240 cm use of a magnetic doctor blade is recommended.

Monforts offers a wide range of different doctor blade systems – also in combination – to meet the individual requirements:

The coating systems are available in four versions – basic, multi-functional, universal and multi-functional. The basic version, for example, offers manual adjustment in two positions for air knife and roller knife coating and printing without magnet for working widths of up to 240 cm.

The Multi-functional version with two position manual adjustment is designed for magnetic knife coating with a working width of up to 240 cm and screen printing. The Universal version features motorised adjustment with three positions for foam coating, roller knife coating and magnetic knife coating; for working widths above 240 cm.

The fourth, Multi-functional version with three position motorised adjustment has been designed for direct fabric feed coating applications using printing templates and operating modes with magnetic roller knife and air knife as well as roller knife coatings.

Monforts can also provide Ex-proof ranges for solvent-based coatings and for high temperature processes up to 320°C such as, for example, PTFE sintering.

All Monforts coating systems feature simple and user friendly PLC techniques with on-screen visualisation for all operating modes. Recipe management for different coating processes are integrated in to the proven Qualitex control system of the Montex stenter.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more