H&V eliminates forever chemicals

Ross Ward, chief commercial officer at NIRI, outlines how nonwovens manufacturers can innovate and thrive in response to imminent restrictions on the use of PFAS.

12th December 2024

Innovation in Textiles

|

Leeds, United Kingdom

As industries increasingly pivot towards sustainability, the fibre and nonwovens sectors face mounting pressure to address a critical challenge – replacing per- and polyfluoroalkyl substances (PFAS).

These man-made chemicals, widely recognised for their water, oil and stain-repellent properties, have earned the nickname ‘forever chemicals’ due to their persistent and non-degradable nature. With growing regulatory scrutiny, the clock is ticking for businesses to find viable alternatives.

PFAS are prized for their durability and repellence, making them essential across industries, including textiles, packaging and food service. However, research has revealed alarming health risks, including elevated cholesterol levels, pregnancy-induced hypertension, reduced vaccine efficacy and links to kidney and testicular cancers.

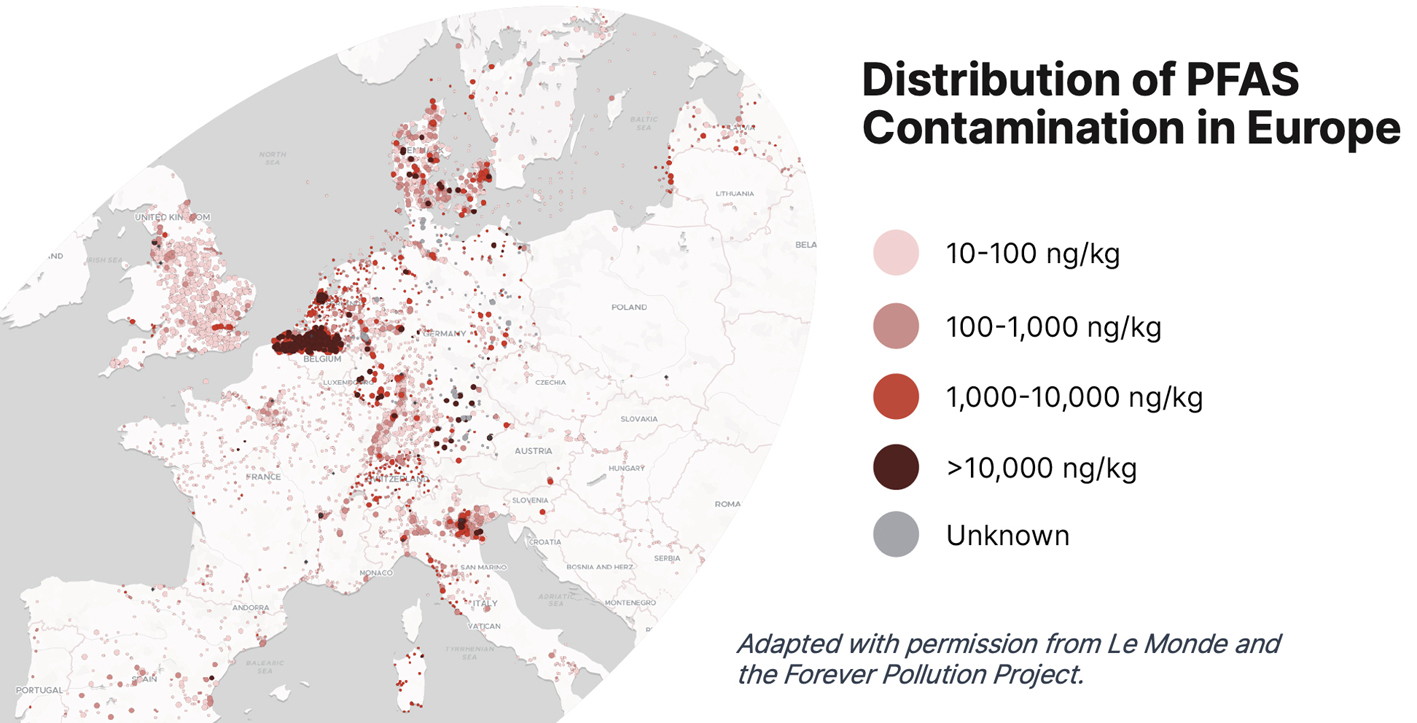

Additionally, the widespread contamination of drinking water and environmental leakage from processing has cemented PFAS as a severe environmental threat.

Legislative push

Significant legislative developments are driving the urgency to replace PFAS. In the US, the Environmental Protection Agency (EPA) plans to ban the manufacture and import of certain PFAS by 2024. States such as California and New York will introduce bans on PFAS in textiles and food packaging by 2025. Similarly, the European Union’s REACH regulations are set to impose severe restrictions on PFAS usage by 2025, followed by an 18-month transition period.

These deadlines provide no room for complacency. Businesses across the nonwovens industry must act now to remain compliant or risk severe penalties and product restrictions. As regulatory pressures increase, the cost of inaction is rising in terms of financial impact and reputational damage. Moreover, the industry is being called to innovate and address growing consumer demand for safer, more sustainable products.

The need for change is not solely driven by regulatory compliance, however, but also an opportunity to lead.

Companies who fail to adapt to such upcoming restrictions may find themselves quickly outpaced by competitors who embrace innovation. The call to replace PFAS is an urgent mandate that will shape the future of the nonwovens sector and now is the time for businesses to invest in research and development to stay ahead of the legislative changes and safeguard their market share.

Alternatives

The search for direct PFAS replacements has been ongoing for years and is challenging. Some materials, such as dendrimers, silicones and polyurethane coatings, show promise in water, soil and stain repellence, but still need to improve in oil repellence – a critical requirement in many industries. PFAS-free coatings based on silicone and polyurethane offer alternatives for medical nonwovens but oil repellence remains an unmet need.

A one-size-fits-all solution is unlikely to replace PFAS across all applications and tailored approaches need to be explored to develop product-specific solutions.

The nonwovens industry needs a multifaceted strategy to address PFAS replacement, including addressing over-specification –

many products are designed to meet performance standards that exceed actual requirements, leading to the overuse of PFAS. Reviewing these specifications can help reduce the reliance on these chemicals.

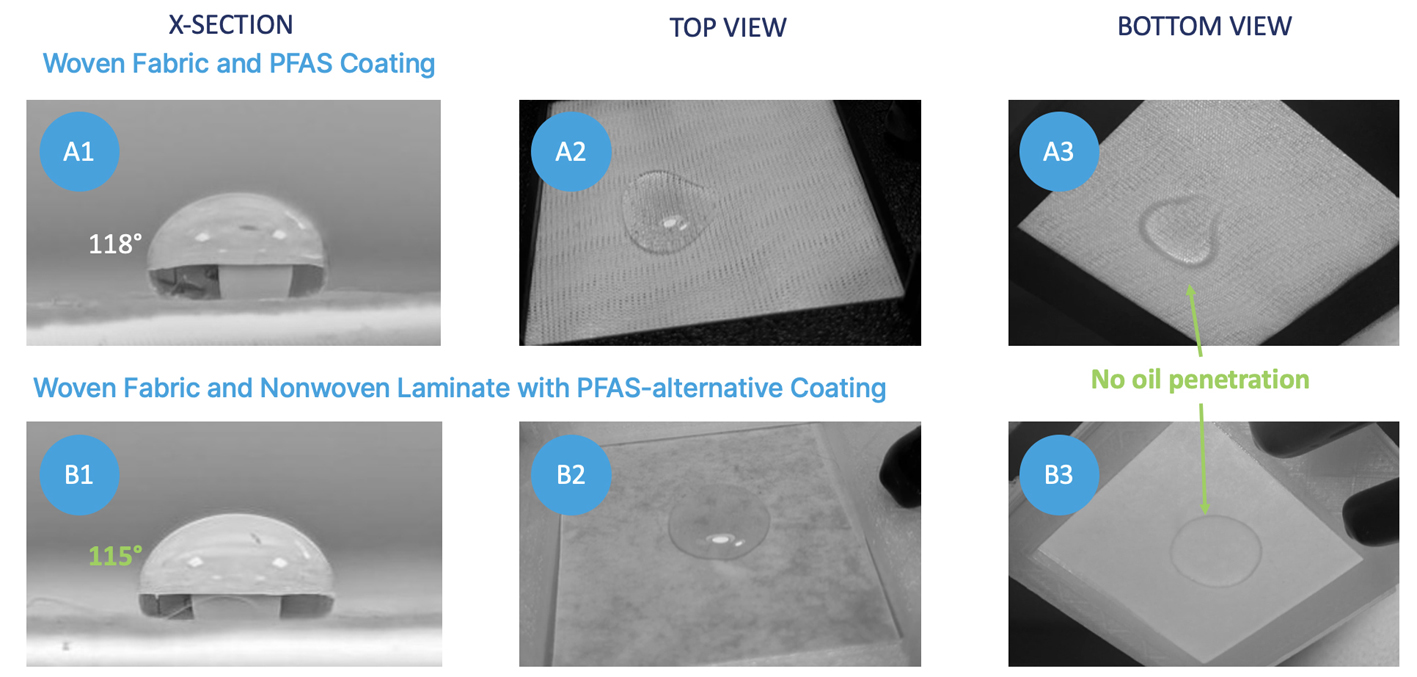

Woven-nonwoven composite

At NIRI, we work closely with clients to develop single-use and durable PFAS-free products by leveraging advanced design strategies. One example is our work on a PFAS-free oleophobic woven-nonwoven laminated composite. After removing PFAS from a woven fabric, its oil repellence dropped substantially. We explored two approaches to counter this – applying an alternative PFAS coating and laminating a woven fabric to a lightweight nonwoven. While both showed improvement, neither fully matched the oil repellence of PFAS-treated fabrics.

Recognising the need for further refinement, the structure of the component fabrics, the coating application and the laminate configuration were modified. This ultimately enabled us to create a PFAS-free composite with oil-repellent properties comparable to the original PFAS-coated fabric.

This highlights the importance of moving from 2D to 3D thinking and not relying entirely on chemistry to address the challenge – rethinking individual components can affect the performance of the entire product system.

Get in touch with NIRI to discover how we can help your business innovate with PFAS-free products, safeguard your reputation, avoid costly fines and market restrictions, and position your business as a leader in a rapidly evolving marketplace.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more