Reiconics collection unveiled at Denim PV

The new purifying unit includes a number of advanced technologies such as a membrane bioreactor, resin bleaching filters and softeners filters.

30th October 2015

Innovation in Textiles

|

Osijek

Olimpias Group, a company controlled by the Benetton family and the European leader in the production of clothing and fabrics, has opened the first European water treatment plant capable to recover up to 100% of the dyeing plant processed water.

The treatment plant is able to recover gradually, up to 100% of the water used and this is the most tangible result of the Wasatex (Water Saving Process for Textile) project financed by the EU as part of the Eco-Innovation programme, with the involvement of companies specialized in engineering systems and water treatment processes.

“In our vision there cannot be sustainability without innovation,” said Gianni Zanella, CEO of Olimpias Group. “Revolutionizing the treatment of the processes water we can significantly reduce water and energy consumption resulting in an important positive impact on the environment, costs savings and improved finished product thanks to the higher quality of the reused water.”

“The project is part of a broader strategy that the company started years ago to support its eco-friendly supply chain. It began with the elimination from our processes of all chemicals harmful for the environment and health.”

Before renewing the water treatment plant the textile factory in Osijek, Croatia, used 1,600m3/day of water where only 10.5% was coming from recovery treatments. Today, the percentage of the recovered water has increased to about 70%, or 1,000m3/day. In this way the water taken from the well is considerably reduce, with obvious environmental benefits and industrial cost reduction, the company reports.

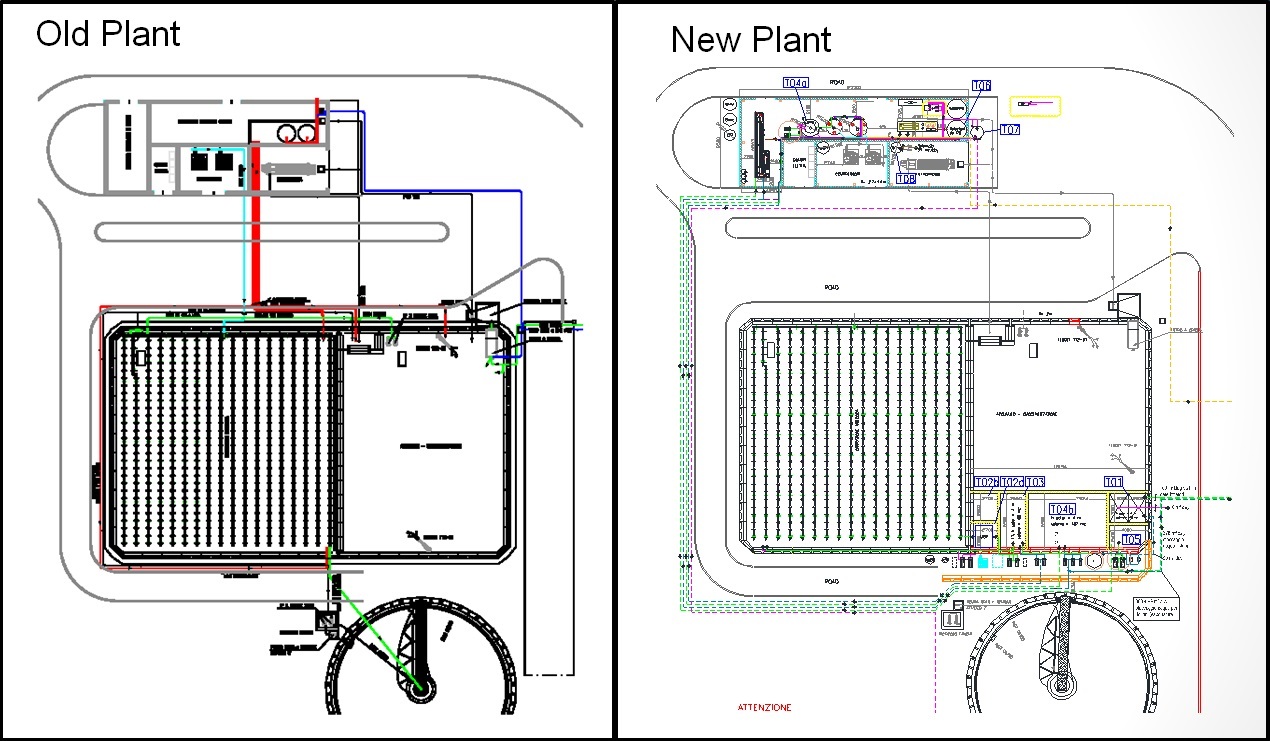

The pre-existing plant could effectively remove only the organic substances but could not treat the inorganic components such as hardness, alkalinity, silica, chlorides, sulphates and heavy metals. Therefore it was impossible to use the outlet water in production.

The new purifying unit includes a number of advanced technologies such as a membrane bioreactor, resin bleaching filters and softeners filters in addition to a reverse osmosis system capable of producing technically perfect and stable water, with very low values of hardness and TDS (Total Dissolved Solids).

The nanofiltration system is also said to allow to recover the brine (NaCl) to be reuse in the dying plant and, finally, the OX system allows to reduce the end discharge, destroying and then remove the complex molecules with high molecular weight, such as COD (Chemical Oxygen Demand) and colour.

The project also provides a considerable energy saving. The purified water has an average temperature of 30°C compared to the 15°C of the well water, hence the energy required for heating in the dyeing baths is significantly reduced and there is as a consequence a further reduction of production costs, according to the manufacturer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more