Testing with real coronavirus

Addressing a key issue in membrane distillation.

30th June 2021

Innovation in Textiles

|

South Korea

The Korea Institute of Civil Engineering and Building Technology (KICT) has announced the development of a stable performance electrospun nanofibre membrane for turning seawater into drinking water by the membrane distillation process.

Membrane wetting is the most challenging issue in membrane distillation – if a membrane exhibits wetting during the process, it must be replaced. Progressive membrane wetting is especially problematic in long-term operations since it leads to inefficient distillation and the feed flow through the membrane creates low-quality permeate.

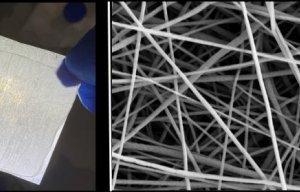

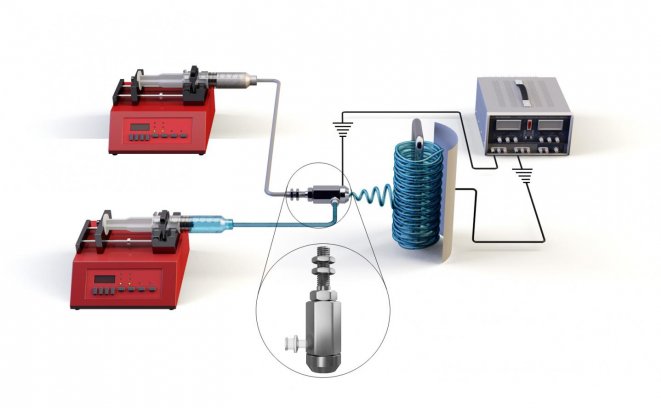

The co-axial electrospun nanofibre membranes developed by Dr Yunchul Woo’s research team at KICT resolve this problem and also improve the long-term stability of the membrane, A three-dimensional hierarchical structure is formed by the nanofibres in the membranes for higher surface roughness and hence better hydrophobicity.

The team used poly(vinylidene fluoride-co-hexafluoropropylene) as the core and silica aerogel mixed with a low concentration of the polymer as the sheath to produce a composite membrane with a superhydrophobic surface. Silica aerogel exhibits a much lower thermal conductivity compared with conventional polymers, leading to increased water vapor flux during the membrane distillation process due to a reduction of conductive heat losses.

Previous studies using electrospun nanofibre membranes in membrane distillation applications operated for less than 50 hours although they exhibited a high water vapor flux performance.

The fabricated co-axial electrospun nanofiber membrane was applied for 30 days with 99.99% salt rejection.

The membrane operated well without wetting and fouling issues due to its low sliding angle and thermal conductivity. Temperature polarization is another significant drawback in membrane distillation since it can decrease water vapor flux performance during a membrane distillation operation due to conductive heat losses. This is also avoided with the KICT membrane.

Dr Woo’s research team note that it is more important to have a stable process than a high water vapor flux performance in a commercially available membrane distillation process. Dr Woo said that

“The co-axial electrospun nanofibre membrane has strong potential for the treatment of seawater solutions without suffering from wetting issues and may be appropriate for real-scale membrane distillation applications,” Dr Woo said.

According to the World Health Organization, about 785 million people around the world lack a clean source of drinking water. Despite the vast amount of water on Earth, most of it is seawater and freshwater accounts for only about 2.5% of the total. Desalination is one of the chief methods for turning seawater into clean drinking water.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more