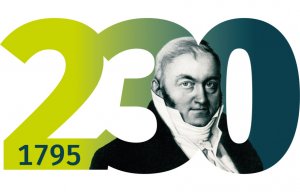

Rieter celebrates 230th anniversary

The four leading brands are specialists in supplying technology components to the textile industry.

8th July 2015

Innovation in Textiles

|

Winterthur

Bräcker, Graf, Novibra and Suessen have presented their newly developed products at ShanghaiTex 2015, the international exhibition for textile machinery that took place in Shanghai last month.

The four leading brands are specialising in supplying technology components to the textile industry and together form an international provider of components for all spinning technologies.

With the help offered by the experienced sales team and the comprehensive display of premium products, the visitors were able to see and compare the premium products from the four manufacturers.

Bräcker presented the two latest spinning rings redORBIT und OPAL. The redORBIT and the OPAL rings were developed in response to the demands of today’s fast paced spinning industry, where the spinning mills have to work with very tight cost control, whilst adapting quickly to the ever faster changing markets, according to the company.

Graf is a specialist in the field of card clothing and combing articles. The advanced clothing magnifier provided the opportunity to visually demonstrate the precision of the Graf card clothings. “The numerous visitors could thus be convinced of the high-quality products first-hand,” said the company.

Novibra, the leader in spindle technology and the 100% in-house spindle maker, presented its wide range of spindles. The high-speed spindle and modern clamping crown CROCOdoff attracted attention during the exhibition, according to the company.

“As the quality demand for textile components is increasing faster than ever before, the products from Novibra presenting the highest quality of spindle are becoming more and more popular in China,” the company explained.

Suessen presented the new compact spinning system EliTeAdvanced for short staple fibres and the Top Weighting Arm HP-GX 4010plus for roving frames.

The technical features of the components impressed the visitors, who were extremely interested in the possible savings in energy, consumables and maintenance effort, as well as in the increased yarn production, lower ends-down rates and improved yarn quality parameters, offered by the new system.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more