PrimaLoft and Fiberpartner announce new global license agreement

Accelerator additive promotes hydrolysis and speeds up material consumption and decomposition by bacteria.

11th November 2024

Innovation in Textiles

|

Japan

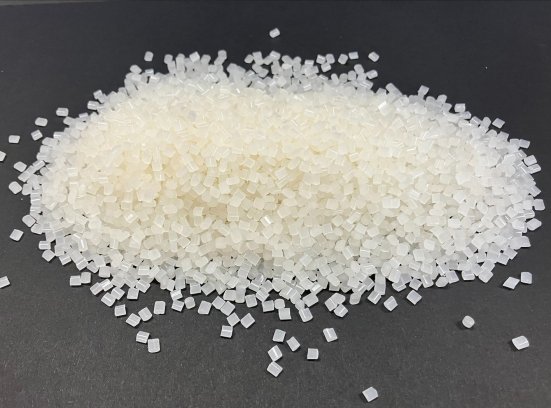

Teijin Frontier’s Biofront polylactic acid (PLA) resin, which biodegrades faster in oceans, rivers and soil compared to conventional PLA products, is now available globally.

The incorporation of a novel biodegradation accelerator in the polymer promotes hydrolysis and speeds up material consumption and decomposition by bacteria and fungi compared to PLA polymers without additives.

Biofront resin exhibits rapid biodegradation performance even in marine and soil environments, where there are fewer bacteria and fungi than in high-temperature, high-humidity composting systems. The decomposition period can be further controlled by adjusting the loading and incorporation parameters of the accelerator.

Another advantage of Biofront resin is its ability to be processed like conventional PLA polymer resins used in films and injection-moulded and extruded products, in addition to being used in fibres for textiles and nonwovens.

Biofront PLA resin will help reduce microplastics, thanks to its accelerated biodegradation rate, and to reduce CO2 emissions during the product lifecycle since it is made from plant-derived raw materials.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more