Polyester renewal plant up and running

Storing massive amounts of heat for up to 24 hours with very little loss.

27th June 2024

Innovation in Textiles

|

Longview, Texas

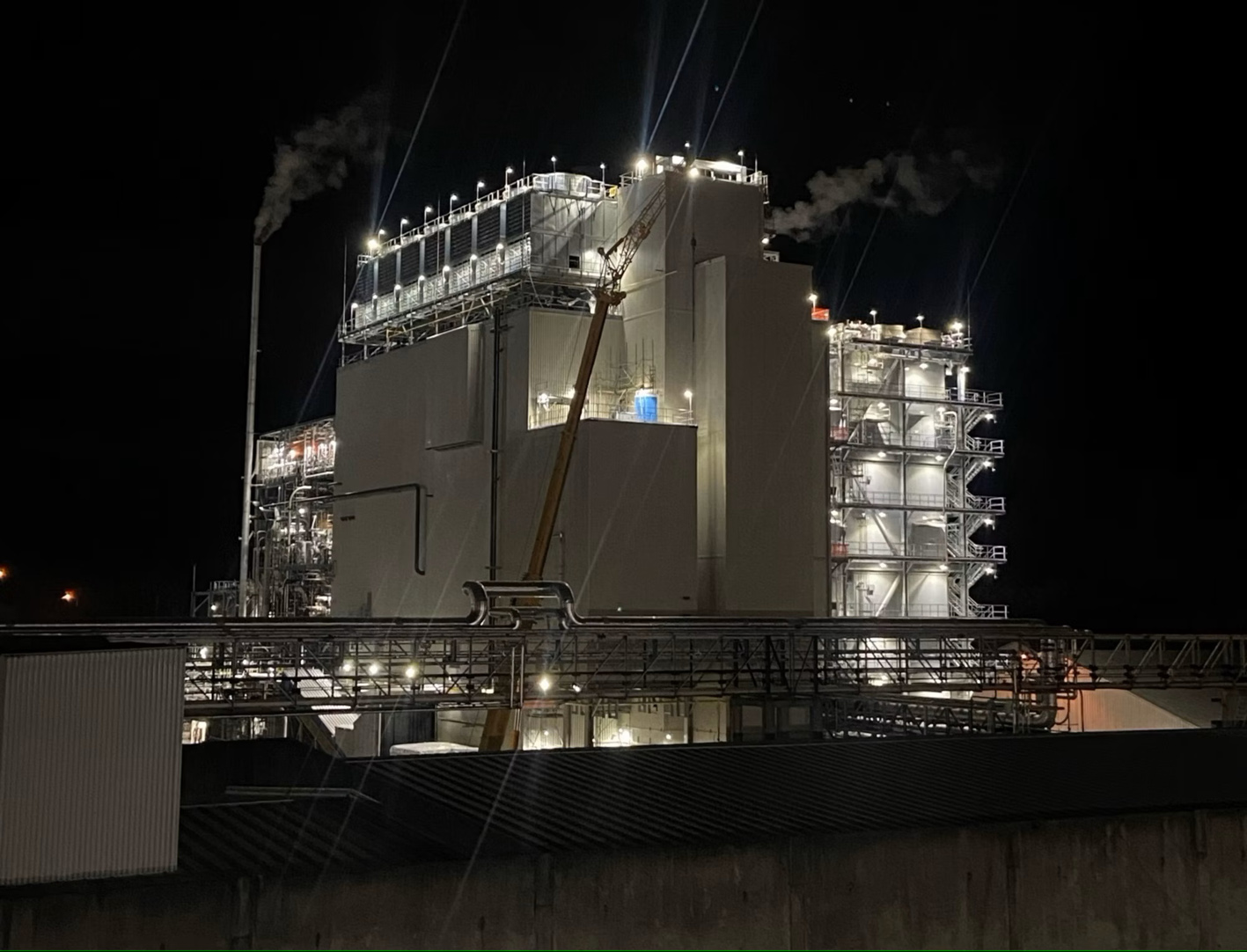

In March this year, Eastman announced the location of its second molecular recycling plant for hard-to-recycle polyester waste is to be located in Longview, Texas.

The first plant, in Kingsport, Tennessee, also began initial production in March and is already generating revenue and on target to earn around $75 million for the company in 2024.

The company’s next-generation methanolysis technology allows such waste to be broken down into the monomer building blocks for polyester that can be used again without compromising performance in a material-to-material high-yield loop.

The Kingsport and Longview plants are aimed at meeting Eastman’s ambitious goals of recycling 125,000 tons of polyester by next year, and double that volume by 2030.

Clean energy

The plan for the new Longview plant, however, will also use a relatively new energy technology – thermal batteries – on a scale never seen before, in order to achieve zero-carbon process heat.

Eastman is currently negotiating an award of up to $375 million from the US Department of Energy’s Office of Clean Energy Demonstrations (OCED) programme in order to enable this, and address two global challenges at once.

Eastman has been collaborating with Rondo Energy to deploy thermal batteries for the project. Rondo Heat Batteries (RHBs) are essentially modular units containing thousands of tons of brick and coils of metal – much like those in a toaster. RHBs transform intermittent renewable power – in this case, much of it from new, on-site solar – into heat in excess of 1,000°C. The brick batteries can store massive amounts of heat for up to 24 hours with very little loss.

By incorporating thermal batteries fed by renewable energy, Eastman will be able to recycle hard-to-recycle polyester waste and produce new, recycled materials with up to 90% fewer greenhouse gas emissions than materials produced with fossil feedstocks. PepsiCo has already signed a contract to use Eastman Renew materials from the Longview facility to create more sustainable packaging with a much lower carbon footprint.

Critical innovation

According to John O’Donnell, CEO of Rondo, the project demonstrates how collaboration can deliver a multiplier effect with cutting-edge technologies.

“Our work with Eastman illustrates how innovation and collaboration are essential to address great world challenges,” he said. “Years of innovation and development by Eastman in molecular recycling combined with Rondo’s expertise in thermal batteries have delivered a moment where these technologies can be deployed together at large scale.”

Neil Brown, an Eastman engineer who is a leader in assessing renewable energy, believes thermal batteries could be a critical innovation for industrial decarbonisation.

“Anywhere there are great needs for process heat – and Eastman uses a lot of heat to power our processes – thermal batteries can be a solution because you’re able to store heat for so long with so little loss. Another plus of building this new facility at an existing site is that if we run into challenges as we’re integrating the new thermal technology, we have backup steam and power systems in place to allow continued operations.”

In addition to the clean energy and circular economy advantages, there will be tangible benefits for the community. Eastman has committed a $20 million investment for a comprehensive community benefit plan that is part of the DOE award. The overall Longview project will create 1,000 temporary construction and trade jobs and 200 full-time jobs when construction is complete in around 2027.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more