Performance Days April 2020 cancelled

Opinion

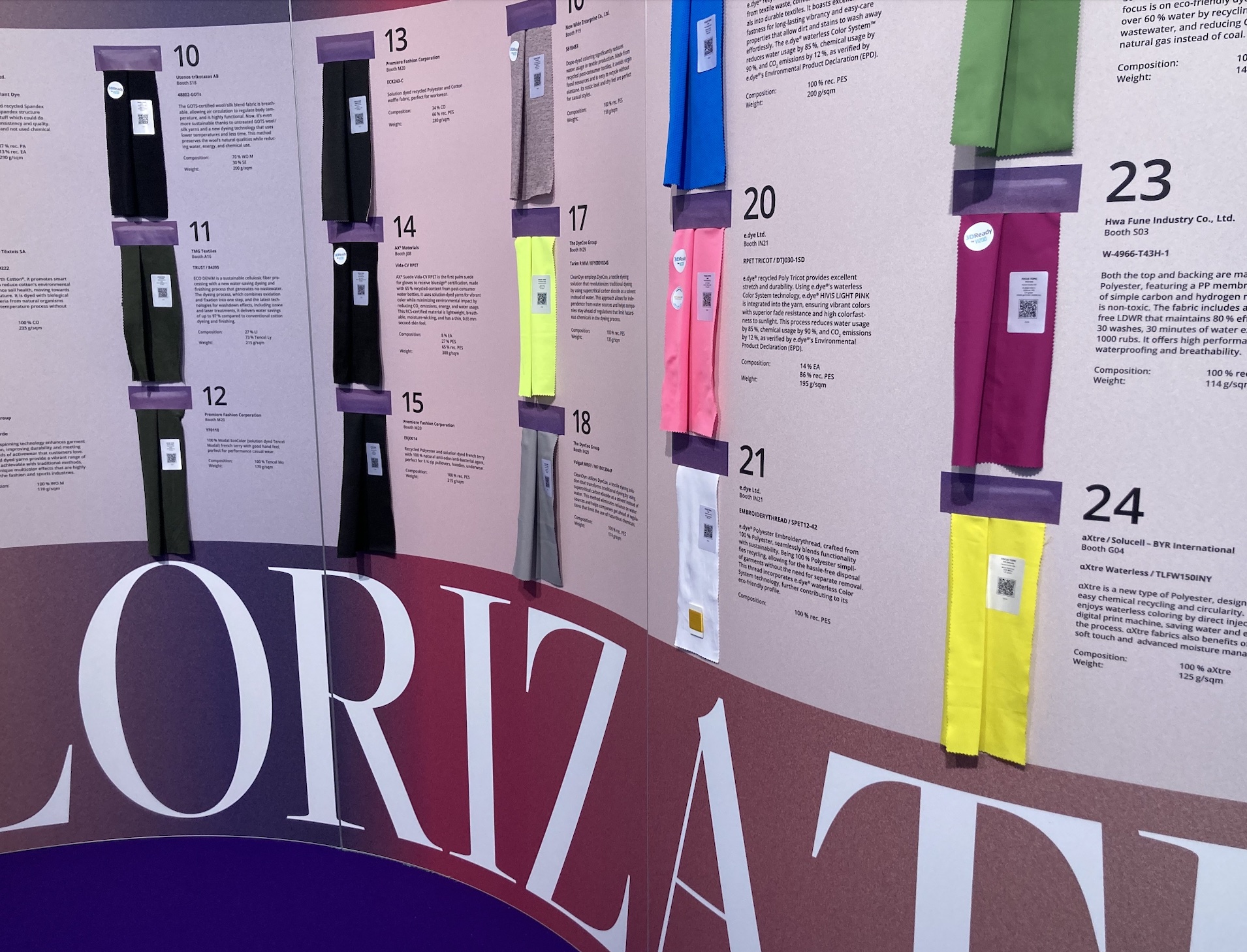

Exhibition showcases solutions to reduce negative environmental impact of colouration process in sportswear industry.

30th October 2024

Anne Prahl

|

Munich, Germany

This month's functional fabric fair Performance Days, sought to shine a spotlight on issues and solutions around textile colouration, focussing on innovative dyeing technologies and processes that reduce water, energy consumption and the use of chemicals, including a growing number of dyes and inks made from alternative raw materials.

Colour in performance textiles

In addition to functionality, colour is a key driver of consumers’ purchasing decisions for sports and outdoor clothing, whether for performance, leisure or fashion use.

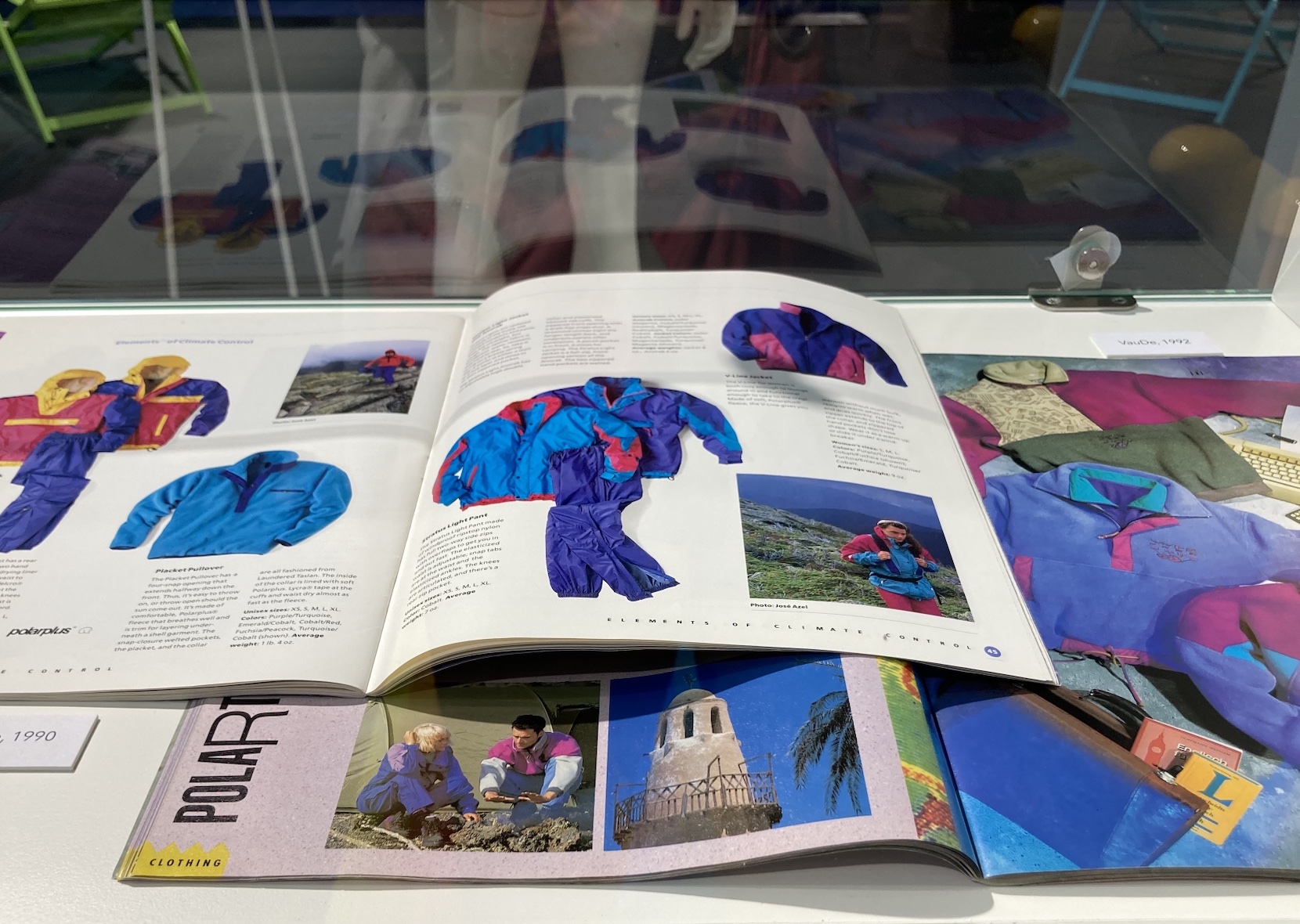

An inspiring exhibition of the history of colour in outdoor clothing by Utah State University's Outdoor Recreation Archive enabled visitors to reflect on the meaning of colour used for functional textiles and accessories, while setting the backdrop for conversations around the environmental impact of textile colouration.

The showcase focussed on how brands have used colour, based on an impressive collection of 6,000 outdoor clothing catalogues from 900 outdoor gear companies dating back to 1900 and featured two distinct themes, ‘Standing Out’ and ‘Blending In’. While ‘Standing Out’ utilises bright colours to make bold style statements or enhance visibility and safety, ‘Blending In’ employs camouflage prints and draws inspiration from natural, seasonal colours. As illustrated by the archive, cultures across the globe have used organic substances like minerals, bark, berries, leaves, wood, roots, fungi, lichens, and even insects to colour their clothing for millennia.

Beyond appropriate colour choice for the intended end-use, it is crucial that intentionally strong colours don’t fade to support the garment’s longevity. Additionally, it is important how colour performs on different types of textiles, and it can be difficult to achieve strong coverage on stretch performance fabrics as they often suffer from unattractive grin-through.

To address this issue, The Lycra Company have developed Lycra Chroma fibre, which enables deeper, richer colours and exceptional colour uniformity for a variety of nylon and wool fabrics. The fibre is engineered to eliminate any elastane shimmer-through on activewear, intimate apparel and hosiery.

Textile colouration, especially dyeing, has a massive environmental footprint and it is therefore critical to accelerate the industry’s efforts to improve existing and innovate new, cleaner and resource-efficient colouration technologies and processes. The trend forum therefore featured alternative methods and technologies ranging from solution and waterless dyeing and natural coloured cotton to natural dyes, while the innovation forum presented additional future solutions and more experimental projects.

Evolution versus revolution

There is significant focus on engineering colouration processes to reduce water, energy and harmful chemical use and solution dyed textiles have been featured at Performance Days for several seasons now. While this process has high minimum order quantities and is generally recommended for synthetic fibres, it was interesting to see a solution dyed Modal Tencel French terry, as well as a polyester cotton blend by Premiere Fashion Corporation.

As suggested by textile consultant Phil Patterson during a panel, while most of the current focus is on new technologies, which may take a long time to scale, more attention should be paid to improving existing machines and processes, as this can significantly reduce environmental impact during the dyeing process.

Suppliers like Utenos Trikotazas have been tweaking their conventional dyeing processes to reduce water, energy and chemical use. The company presented wool fabrics that have been dyed in cold water with water-based dyes, leading to the reduction of water and energy consumption, as well as providing the opportunity to reuse the dye bath to dye one or two more batches. They also use only 50% of the supplier recommended softeners and believe that this new approach to wool dyeing brings out the inherent quality of wool.

Another solution is to update and optimise older machines to enable cleaner processes and resource efficiency. An innovative solution was presented by Carmina Ferri, Founder and CEO at Care Applications, who have developed mechanical devices to be installed in existing dyeing machines, to reduce water, energy and chemical use dramatically.

Colour spraying methods not only create stunning aesthetics but can also contribute to water and energy reduction when compared with conventional dyeing. Domiles presented their collection of sprayed polyester, nylon and cotton textiles and garments, where dye is directly sprayed onto the fabric through spray heads and can also be combined with a printed layer for additional detail.

Another eye-catching example of the spray dyed look was a new collection produced by Eurojersey in partnership with Tintoria Emiliana. The companies have worked together to create a unique painted effect on a range of pique, rib with embossed rib effect and mesh by utilising an airbrush and brush dyeing treatment.

Digital printing is another alternative to water-intensive dyeing and BYR International introduced a new generation of synthetic material designed for easy and cost-effective chemical recycling that delivers a super soft hand-feel, quick-dry attributes, low temperature dyeing and easy digital printing in multiple blends, such as aXtre blended with wool and modal.

The unique merino fabric showcased by Südwolle Group utilises a yarn spinning technology that improves the durability of the garment, while the variety of colours create a stunning multi-colour look. The company converted an old machine to create a bespoke process whereby white yarns are printed by nozzles, as they go through the machine. Interestingly, the process can be programmed to achieve precisely placed patterns in line with the garment’s intended design.

Twine Solutions’ digital yarn thread dyeing technology is another interesting innovation making use of printed threads and yarns. The technology enables waterless dyeing at the level of the individual thread, as white yarn runs through a pre-heated chamber and is penetrated by dyes as part of the sublimation process.

Initially the company developed their TwineX1 machines for sampling and small production needs, and several brands and retailers are already using this as an in-house tool for designers and developers. The range was expanded to include TwineX4, which is suitable for small to medium production runs.

Fostering a new mindset

In conversation, textile companies A. Sampaio & Filhos -Texteis and Utenos Trikotazas shared their experiences of experimenting with new processes and raw materials to provide cleaner and resource-efficient textile solutions. Working with botanical and biological dyes, both companies highlighted the need to change their customers’, and ultimately the consumer’s mindset on colour, as although interest in natural colours is growing, commercial demand is still lacking.

As a spokesperson for Utenos Trikotazas pointed out, the industry has yet to lose their fear of fading colours. This point was echoed by Phil Patterson, who stated that for new dyeing innovations to be scaled up successfully, current colour fastness standards are unnecessarily high. In addition, the requirement of excessive standards prohibits the urgent reduction of heat and water use in the textile industry.

Many innovators are working with alternative, natural raw materials such as algae, whether this is used for textiles or colouration processes. Start-up Algaeing creates both dyes and inks from this versatile material and the company currently has a range of over 25 bio colours. While the dye can be used on synthetic fabrics including polyamide and polyester, both recycled and conventional, the ink can be used on all fabric types. Algaeing saves 74% greenhouse gas emissions and 98% water compared to conventional dye and ink production and produces clean water at the end of the dyeing process, which has significant environmental and financial advantages. Due to its perceived health benefits from use in the food and cosmetics industry, the company’s products are currently mostly used for next-to-skin textiles, such as underwear.

More experimental approaches were displayed in the innovation forum and included samples by The Textiles Circularity Centre (TCC), which works on circular supply chains, materials innovation and consumer experience to drive future solutions for a circular textile industry. Their collection demonstrated the potential of functional natural dyes that can be added during the fibre wet spinning process to provide antibacterial properties, while eliminating the need for toxic chemicals used in the traditional viscose manufacturing process.

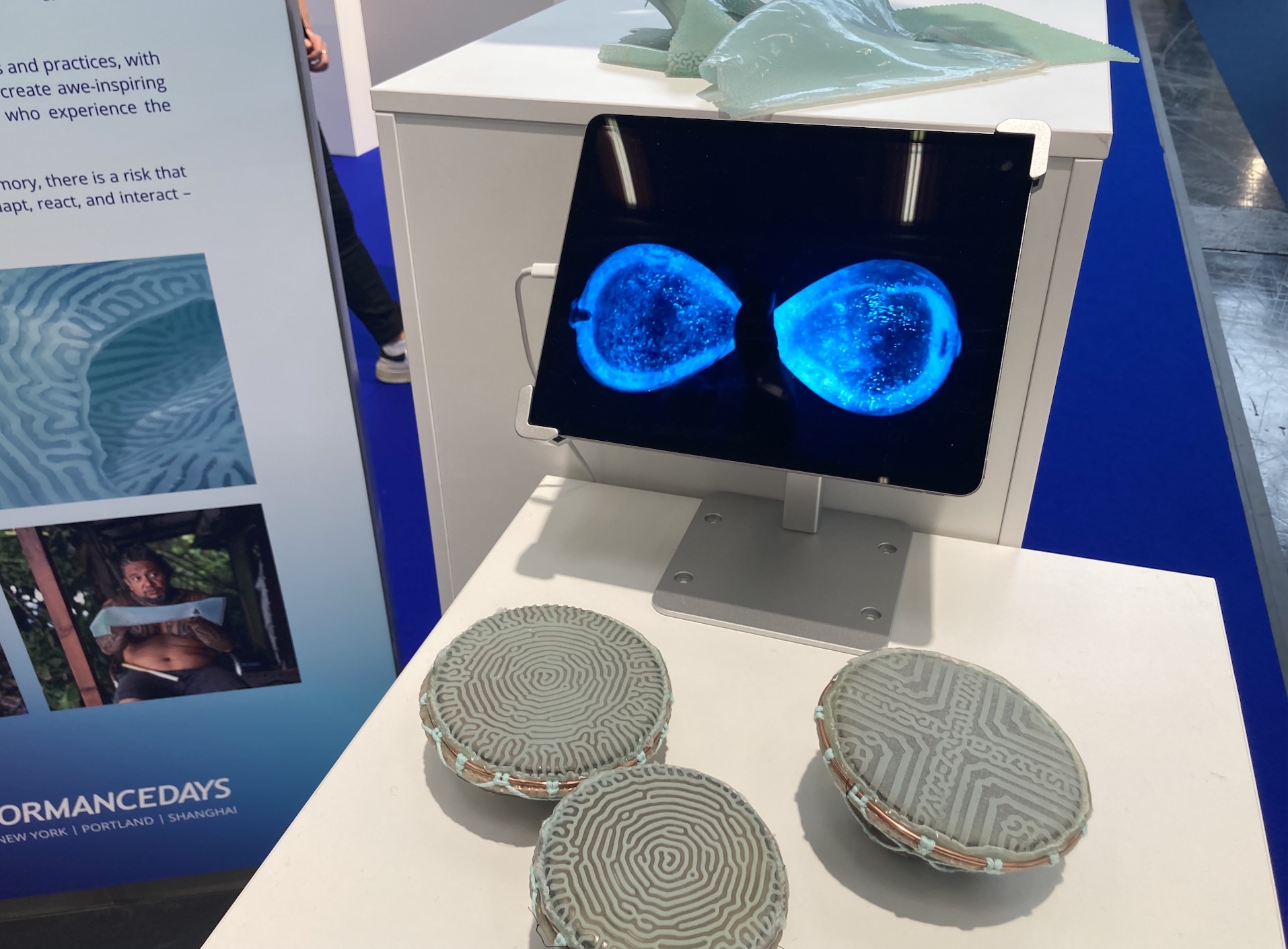

Not strictly speaking a future colour solution but a concept for changing surface aesthetics, biodesigner and engineer Christopher Bellamy showcased his project bio.crafted, which encapsulates bioluminescent microalgae to enable a type of living material capable of changing its appearance through light emission in response to touch.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more