Freudenberg’s comfortemp goes sustainable

Freudenberg Performance Materials will present the world’s first padding made from fiberballs at ISPO MUNICH 2017.

10th February 2017

Innovation in Textiles

|

Weinheim

Freudenberg Performance Materials has presented a new dimension in thermal insulation, comfortemp fiberball padding, at the leading sportswear and outdoor trade show, ISPO Munich, which took place in Germany this week, attracting more than 85,000 trade visitors from 120 countries. At ISPO Munich 2017, Freudenberg Performance Materials also presented the entire comfortemp product family.

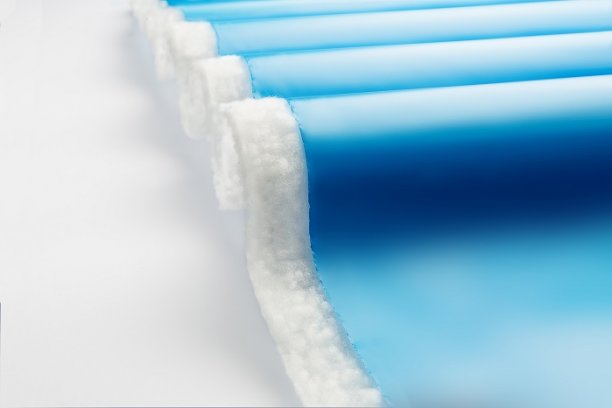

The first ever padding made from fiberballs combines the advantages of loose down fillings and padding in a quality that has not previously been achieved, the company reports. For example, thermal insulation is as much as 80% higher than conventional padding while the new material is as light and soft as down, according to the manufacturer.

“Padding made from loose fiberballs has been around for quite a while. Up to now, however, it has not been possible to produce a continuous padding from it. With the comfortemp fiberball padding, we have succeeded in uniting the advantages of existing technologies and thermal insulation products while offsetting the disadvantages. The comfortemp fiberball padding is the world’s first padding made from interconnected fiberballs,” explained Ulrich Scherbel, General Manager Freudenberg Performance Materials Apparel.

According to the manufacturer, the advantages of comfortemp fiberball padding for consumers include higher thermal insulation comparable to down. The thermal insulation of comfortemp fiberball padding is said to be 50 to 80% higher than conventional padding. The material consists of many small fiberballs, between which are many small air pockets.

The new material is also said to be twice as breathable as conventional paddings, thanks to the many small air pockets and a special pore structure giving the material high permeability.

The new comfortemp fiberball padding also has a uniform structure that is designed to ensure no cold spots can occur in the padding. This structure is even maintained after washing. In addition, the new product is a genuine alternative to down, meaning that athletes and other active people do not need to worry about animal protection.

The advantages of comfortemp fiberball padding for garment manufacturers include increased design freedom, easier processing, due to the ability of the padding to be stitched like a conventional padding, saving considerable costs, and lower transportation costs, as it can be vacuum packed.

A lifestyle brand Napapijri launched its Superlight Parka for the 2017 Fall/Winter season utilising its owned THERMO-FIBRE technology powered by comfortemp fiberball padding at the show. “The collaboration between Freudenberg Performance Materials Apparel and Napapijri gave a boost to the development of the fiberball padding”, the company reports.

The lifestyle brand focuses on product innovation for solutions that improve others’ lives. “From the beginning, they showed great interest in a padding made from fiberballs that would boost the performance of their parkas and winter jackets,” said Ulrich Scherbel.

Napapijri’s already-owned THERMO-FIBRE technology was therefore evolved from filling balls to a padding powered by comfortemp fiberball padding. For our own part, we will begin marketing comfortemp fiberball padding at ISPO Munich 2017.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more