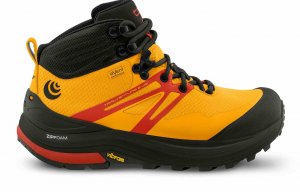

Topo Athletic chooses eVent laminates

The Disappearing Shoe concept introduced at ISPO Munich.

4th December 2024

Innovation in Textiles

|

Ho Chi Minh City, Vietnam

Cirql, the Ho Chi Minh City, Vietnam-based subsidiary of OrthoLite, has introduced Cirql Zero, a new industrially compostable, biodegradable foam innovation for footwear midsoles at this week’s ISPO sports show in Munich.

Footwear brands have been searching for a trusted, fully biodegradable midsole material for many years, according to Matt Thwaites, vice president and general manager of Cirql.

“The midsole has always been a challenge because brands need the performance properties to go with the compostability of a biodegradable version,” he explains. “After a diligent development and testing process, we can now provide a price-competitive, scalable, industrially compostable and biodegradable midsole component to our global footwear brand customers.”

With a commitment to keeping shoes out of landfills, Cirql now offers footwear brands comprehensive solutions that address both the production and end-of-life phases of footwear materials, emphasising biodegradability, recyclability, manufacturing adaptability and scalability.

At ISPO Munich has introduced the Disappearing Shoe concept product, with patent-pending Cirql Zero which uses a proprietary polymer compound made via supercritical foaming with inert gases.

As a lightweight, comfortable and resilient midsole, it can be customised for multiple footwear categories, from athletic to luxury, and ‘tuned’ to meet the design specs required by brands. At the end of the product’s life, Cirql Zero exceeds the industrial compostability testing standard of 90% degradation in 180 days. It will be fully compostable in industrial composting.

The midsole foam can be produced using supercritical foaming (SCF) technology in an autoclave process. This flexibility ensures that Cirql Zero is accessible to a broad range of manufacturers, streamlining its integration into existing production processes and paving the way for its rapid adoption across the global footwear industry. As such, it is the first midsole foam of its kind that can be scaled to hundreds of millions of pairs of shoes annually.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more