Stäubli to present latest technology at Techtextil 2017

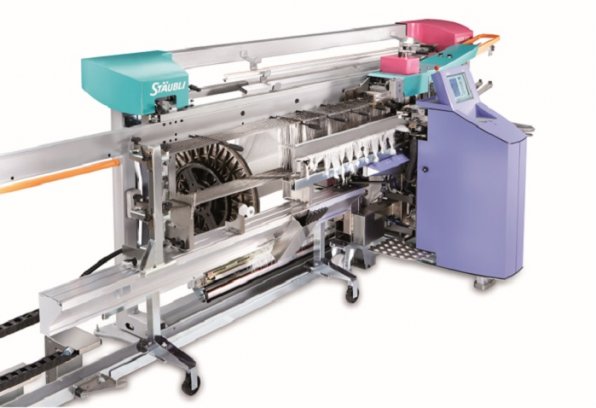

One of the recent developments is Magma T12 warp tying machine for an optimised workflow in the mill.

9th May 2018

Innovation in Textiles

|

Pfäffikon

Stäubli has been one of the leading manufacturers of high-speed textile machinery for more than 125 years, expanding its range from shedding solutions for weaving machines, weaving preparation systems, and complete carpet weaving systems, to include textile machinery dedicated to the production of technical textiles.

Now, the company offers a number of technologies for a variety of markets, including automotive, medical and aerospace. One of the recent developments is Magma T12 warp tying machine for an optimised workflow in the mill, which ties monofilaments, coarse multi-filaments, PP ribbons, bast fibres, coarse staple fibres, and many other fibre types. It has been developed for universal application ranging from coarse technical yarns to the medium yarn-count range. Its rigid design includes an optical double-end detection system.

Another innovation is the TF weaving system for sophisticated reinforcing fabrics. The system is said to offer unlimited weaving possibilities, whether for flat, spacer, or complex multi-layer fabrics and 3D fabrics. Specific requirements in terms of stiffness, impregnation capacity, drapability, or fail-safe-behaviour, etc, can be fulfilled.

Featuring the latest shedding machines, in combination with the double-rapier weft insertion system and a special slaying motion, the TF weaving system is designed to allow high-volume production of up to very thick and/or dense fabrics and efficient processing of a wide variety of technical and highly sensitive yarns, such as glass fibre, carbon, Kevlar, or similar.

For the automotive industry, Stäubli supplies shedding solutions for airbag weaving, traditional airbags woven on frame weaving machines, and OPW (one-piece-woven) airbags produced on modern Jacquard weaving machines. “Airbag fabrics demand important stroke forces during weaving,” the company explains. “The solid construction of the latest generation S3000/S3200 electronic rotary dobbies provides the basis in frame weaving for supporting these forces while running reliably at high speeds day in and day out, offering important longevity.”

“Frame weaving pre-requisites, such as perfectly prepared warps, gain in importance when it comes to deliver the automotive industry with its zero-error specifications. The weaver has to produce more first-class fabric, while staying competitive. Using the Safir automatic drawing-in installations, equipped with active warp control features, such as optical recognition of double ends and colour/yarn type repeat management, allows the weavers to meet these strict requirements.”

For the production of OPW airbags, Stäubli provides the LX Jacquard machine series. They feature balanced cinematics, a coaxial drive shaft, and an optimised internal airflow, as well as optimum sized chassis. These features are designed to ensure clean interiors, controlled temperature in the machinery housing, the support of beams and bearings and make the machines handle great payloads and precise operating at highest production speeds.

The latest models in the LX series, the LXL and LXXL are specifically developed for large-sized designs and can be equipped in a format range of 6,144 to 25,600 hooks. By combining two LXXL machines, formats up to 51,200 can be achieved.

With its Alpha 500 series carpet weaving systems, Stäubli provides a product range for any kind of rug or wall-to-wall carpet.

.jpg)

“Weavers can count on the Alpha 500 Leantec model for weaving superior high-quality synthetic grass, with a weaving width of up to 5.3 metres. The Stäubli binding technology allows the optimum orientation of the piles for a wide public, ranging from major league sports facilities suppliers, to public services and garden centres,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more