Italian-made for Mars

Just one month after opening its new textile engineering laboratory specialising in flat knit engineering (see: Innovation lab for engineered flat knits opens in LA ), Los Angeles based Fabdesigns, Inc., has announced that its flat knitted armoured compression space suit has been selected as one of the top 20 finalists in the “LAUNCH 2013 Systems Challenge”.

9th August 2013

Innovation in Textiles

|

Outer Space

Just one month after opening its new textile laboratory specialising in flat knit engineering (see: Innovation lab for engineered flat knits opens in LA ), Los Angeles based Fabdesigns, Inc., has announced that its flat knitted armoured compression space suit has been selected as one of the top 20 finalists in the “LAUNCH 2013 Systems Challenge”.

LAUNCH is a global initiative to identify and support the innovative work poised to contribute to a sustainable future and accelerate solutions to meet urgent challenges facing our society. NASA, USAID, the US Department of State, and Nike joined together to form LAUNCH in early 2010 in an effort to identify, showcase and support innovative approaches to global challenges through a series of forums. LAUNCH searches for visionaries, whose world-class ideas, technologies or programs show great promise for making tangible impacts on society.

LAUNCH 2013, is an innovation challenge seeking innovations that will transform the system of fabrics to one that advances equitable global economic growth, drives human prosperity and replenishes the planet's resources.

Fabdesigns says it has developed breakthrough protective space-wear that provides radiation protection for astronauts with a high-degree of flexibility and additional fire-resistance. The dangerous levels of radiation that astronauts are exposed to beyond Earth orbit remains a significant health challenge for deeper exploration of the Solar System, the company says. Fabdesigns has created its highly technical fabrications using industrial flat knitting machinery typically used for making sweaters.

“With the ability to produce ’things’, comes equally great responsibility to human health and the environment to manufacture with minimal impact on the environment,” Bruce Huffa, Fabdesigns executive engineer states.

“Optimizing efficiency, minimizing waste, using less energy, and building manufacturing knowledge are all very important to us,” Huffa adds. “We’re hopeful that the online voting at LAUNCH 2013, which is open to the public, will allow people to become aware of the need to reduce the global manufacturing carbon footprint. We start from the supply chain and product design, which digitally integrate features like pockets, tunnels, and cables, then eliminate most of the cutting and sewing. In our system, we use just the materials needed.”

“Our goal in this project is to protect human beings from hazardous environments and improve not only their chances of survival, but the quality of life afterwards.“

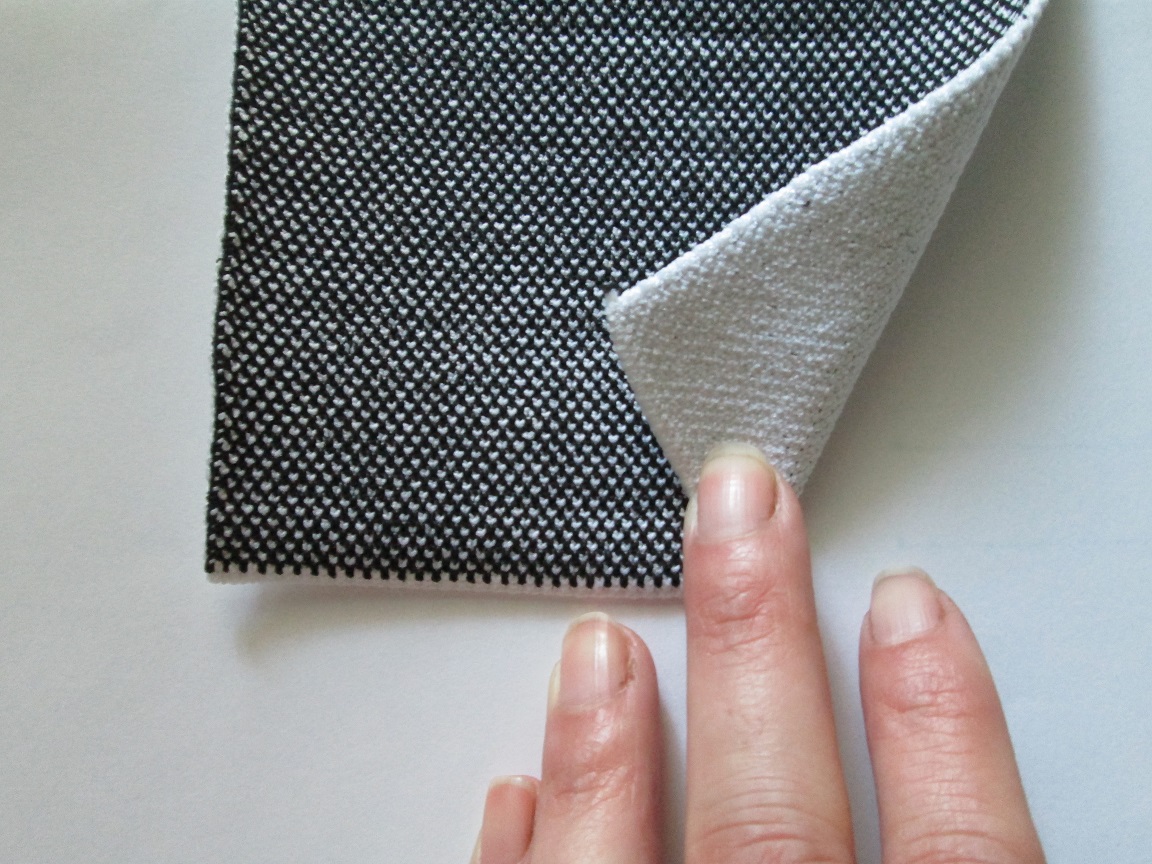

Fabdesigns President and textile engineer, Connie Huffa presents several soft and stretchable 3-dimensional fabric swatches with different textured sides that she calls a spacer. A spacer is a fabric with two face sides and a yarn constructed hollow gap between the faces.

“The initial focus for our fabrication efforts is to meet NASA’s challenge of a potential space mission to Mars, since astronauts are exposed to many different situations that have the potential to cause irreversible harm to the body. This extremely hostile environment requires a sophisticated fabrication that will protect the wearer from hazards emanating from outer space, the space craft itself, and health problems from the human body’s reaction to antigravity conditions,” she says.

She flips a swatch to the reverse. “We hope this combination of highly protective materials, medical grade compression, sensory, and muscular activation techniques, will address the initial need at NASA for improved astronaut health and mobility, and that subsequent products described in our submission, will address the more civilian aspect for protective wear applications in extreme environments on Earth.”

Bruce Huffa explains the technology. ”Each suit panel is comprised of non-terminating yarns. The support areas of the fabric consist of several textile stitch areas of gradient levels of stretch elements, flex, rigid, and restrictive elements, which are integrated into the fabric by mapping the appropriate levels of motion or protection required.”

“These knit stitching techniques create varying degrees of elasticity, rigidity, open channels, tunnels, and zones of specialized yarns integrated into the base fabric. Zones are comprised of threads or yarns, which are isolated into specialized needs, using Kevlar, monofilaments, Spectra, silicon, or other specialty performance yarns knit into the fabric to enable that region to perform a combined protective, biomechanical range of motion, compression, and therapeutic element integrated into that single panel, or series of panels required completing a garment.”

One of several concepts in Fabdesigns, Inc. submission to LAUNCH 2013 plans to address Space Adaptation Sickness (SAS) and muscle loss. It utilizes electro stimulation, with current applied, and sensors receiving data. Much like the function of knitted brace supports and some high tech wet suits currently on the market, Connie explains, this compressive garment combats lack of gravity by: increasing circulation and venous blood flow, delays exhaustion and muscle soreness, optimizes endurance, helps the body remove lactic acid faster, improves strength and power, and encourages positive posture like an orthopaedic training garment.

“On Earth radiation is a danger faced by the military, health care workers, and the first-responder in many different scenarios. Like it or not, this world is becoming more challenging with pollution, disasters like the Fukushima Daiichi Plant, and horribly creative terrorist situations that none of us want to imagine, but are none the less real. Our anatomically correct applications addressing protection as well as comfort, will reach the people who need it much faster as extreme career wear, in military, medical, energy, transportation, safety, protection and first responders,” Connie Huffa concludes.

“The biomechanical attributes are applicable to orthopedic, extreme sports, and other rehabilitative medical conditions. In another project, unrelated to LAUNCH, we are working on a solar powered fabric. Our second concept could be battery powered, solar charged and help reach people in isolated environments. Isolated environments include people in developing countries with lack of DC current. The vital sensors can offer virtual, real time, access by doctors miles or countries away.”

For further information or to vote for the Fabdesigns’ project visit:

www.launch.org/challenges/systems-2013

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more