Added extra from Litrax

Editor’s Viewpoint

Some companies do things big – like the tech giant Google or the mega sports brand Nike, for example. They have their global supply chains, their offices and production facilities all over the world, they employ hundreds of thousands, and they sell their products and services to large swathes of the world’s 7.7 billion population. They truly do have global influence.

11th September 2019

Billy Hunter

|

Hong Kong/Switzerland

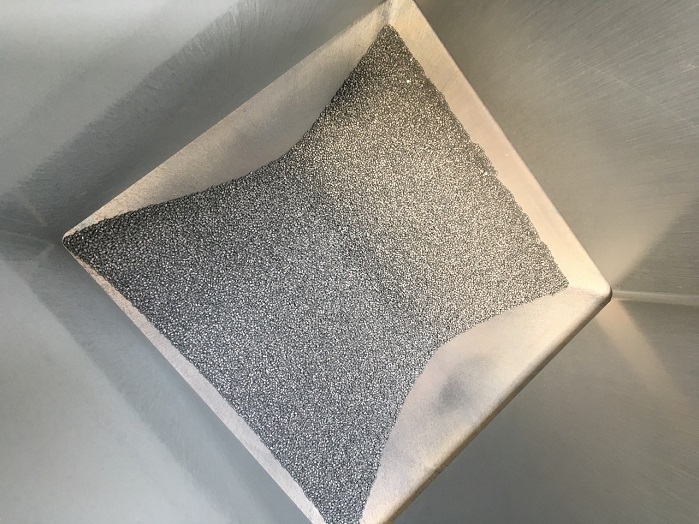

LITRAX provides innovative nano-particle technology for polymer chips, textile materials and consumer products. © LITRAX

Some companies do things big – like the tech giant Google or the mega sports brand Nike, for example. They have their global supply chains, their offices and production facilities all over the world, they employ hundreds of thousands, and they sell their products and services to large swathes of the world’s 7.7 billion population. They truly do have global influence.

Other companies do things in a much smaller way – they don’t own global production facilities, have very few employees and sometimes don’t even have offices. But they can still make a global impact by innovating, developing their own intellectual property and by fostering collaborations and developing partnerships across the world. Their products and services may end up in the homes of millions, but we might not be familiar with them and they’re certainly not household names. They can also have global influence, however.

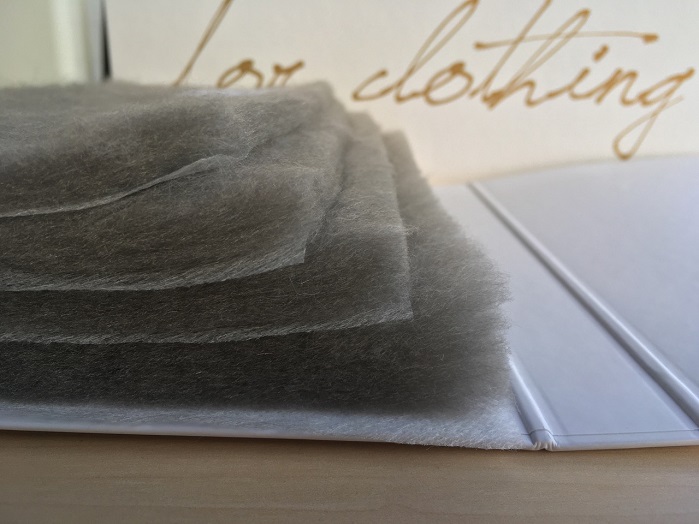

LITRAX supplies both nano particles and chips. © LITRAX

Thoughts become things

One company that definitely fits neatly into the latter category is LITRAX AG Limited, a dynamic Swiss-owned Hong Kong based company which provides advanced, innovative and environmentally conscious nano-particle technology for polymer chips, textile materials and consumer products in several Industries, including automotive, construction, packaging, airspace, agriculture, wearables, medical.

“We partner with global medium-large producers to access and ‘lease’ their global production in Germany, Switzerland, Thailand, India, China, Indonesia. It’s a cost-effective time and location flexible outsourced OEM production model,” says LITRAX CEO Felix Stutz.

“We also partner with national institutes like Centi, Empa and TTRI for testing, research and development. Its more cost effective than hiring PhD’s, and we get access to pools of latest research knowhow.”

LITRAX nano particles are invisible to the human eye. To give you some idea of nanoscale - 10 hydrogen atoms laid side by side measure a nanometre (nm) across, a strand of DNA is 2.5 nm in diameter, while a red blood cell is about 7000 nm wide.

LITRAX partners with renowned spinning and extrusion companies across three continents. © LITRAX

LITRAX’ products are also sometimes invisible in another way – we don’t see its swing tickets on the big brand sneakers or designer clothing for example, but LITRAX products do regularly end up in some of the world’s best-known products from the most renowned brands.

Through its expertise and products LITRAX aims to enable its industry partners to create new markets, increase competitive edge, become more profitable and outperform competition. “We focus on thoughts that ultimately become engineered things,” says Felix Stutz.

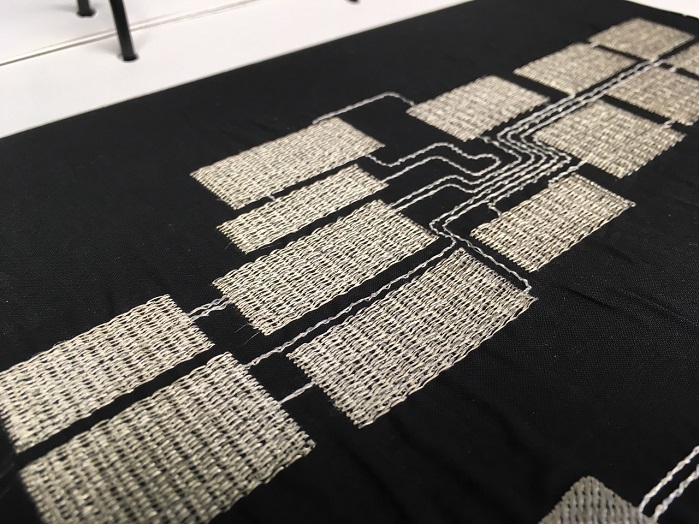

LITRAX is currently focused on the increasing demand for e-textiles. © LITRAX

“As a highly qualified international team of experts, we create almost weekly - new products for special industrial and fashion applications. In textiles, our nanotechnology is among the most advanced for functional fashion, underwear, hosiery, workwear and athletic or outdoor garments. In other areas we provide turnkey and ready-to-use batches, particles or semi fabricates.”

LITRAX supplies both nano particles and chips. LITRAX Nano Solutions provide spray-dried functional blends or single custom designed nano materials in powder form. Depending on the application, these additive blends combine with different thermoplastics such as PET, RPET, PA6, PA6.6, PP, ABS, PE and increasingly compostable or easily recyclable polymers like PLA, PBS and others.

LITRAX creates the appropriate nano powder or master batch (chip) according to the desired characteristics. © LITRAX

“The great advantage of using LITRAX nano technology master batches in granulate or chip form is that they are very easy to use in various dosing systems like volumetric, gravimetric or manual dosage,” explains Felix Stutz. “The use of LITRAX functional additives in chip form significantly facilitates your production process because the risk of formation of additive agglomerate is eliminated due to special core-shell treatment of nanoparticles. Additionally, masterbatch preparations allow to keep the production process dust-free.”

LITRAX’ ready-to-spin masterbatches contain an optimised percentage of functional additive in virgin polymer, helping avoid lengthy blending and extrusion trials. According to LITRAX, this ensures that users get immediate results with ready-to-spin compounds and shorten their R&D times whilst improving speed to market. Small lab scale quantities are available for immediate prototype evaluation.

As well as supplying nano materials and chips, LITRAX also partners with renowned spinning and extrusion companies across three continents, which enables it to offer its customers market-ready quality materials, such as functional staple fibres, performance filaments, films and moulded fabricates.

LITRAX performing masterbatches combines performing additives with various natural and manmade fibres and filaments. © LITRAX

Felix Stutz is keen to highlight LITRAX’ comprehensive professional service. “Customers can access the pool of LITRAX complete project management assistance, under full international NDA (Non-Disclosure Agreement) or MTA (Material Transfer Agreement) protection. This qualifies testing out a particular idea before marketing it at full industrial scale. What a wonderful cut down of your R&D risks and costs,” Felix emphasises.

“We continuously improve our operations, alliances and technologies to ensure that LITRAX products and services meet or exceed the most stringent customer requirements for innovation content, function, quality and flexibility.”

LITRAX performing masterbatches combines performing additives made from organic, chemical and mineral substances with various natural and manmade fibres and filaments, in various polymer forms such as PET, RPET and PA6.

Textile applications include architecture, automotive, fashion, home textiles, interior, and furnishing. © LITRAX

Textile applications include architecture, automotive, fashion, home textiles, interior, and furnishing. Performance textiles can have one or combination of multiple functions such as rapid heating (+13 °C in 10 minutes), cooling, moisture management, skin care, absorption or UV protection, insulation, increased blood flow, metabolism boosters, camouflage for tactical use, anti-odour, bacteriostatic, and others.

LITRAX creates the appropriate functional nano powder or master batch (chip) according to the desired performance characteristics and subsequently performance fibres and yarns are produced with partnering spinners around the globe.

Textile products include POY, FOY, DTY, DDY yarns and texturizing, covering and air texturing processes are carried out by carefully selected partners. Customers can design and create their performance yarn of choice through the LITRAX network, or through their own supply chain or preferred spinning partner.

Performance textiles can have one or combination of multiple functions. © LITRAX

“We support and coach spinning clients with suggestions on combinations of technologies and special cross sections in fibres, to achieve optimum functionality,” Felix Stutz explains.

“On demand, we also bring you together with fabric producers in the country of choice, or simply team up with your preferred fabric partner, in order to ensure continued best quality supply chain for your marketing operations,” Felix Stutz concludes.

LITRAX does some things in a very small way – at nanoscale. As the company says, “We nano anything”. But it is clear that it does other things in a very big way – on a global scale in fact.

E-textiles. © LITRAX

LITRAX is currently focused on the increasing demand for e-textiles and textile wearables with its L14 high conductivity technology (<1 Ohm/cm), supplying knitters and weavers together with a large brand. The technology will also be presented and compared to graphene options at the Dornbirn GFC conference, which takes place this week in Austria.

LITRAX welcomes enquiries from companies interested in developing partnerships for innovation, new markets and profitability.

Further information

LITRAX AG Limited

Contact: Felix Stutz, CEO

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more