Microfibre shedding standard due shortly

Ethanol bath employed to distinguish nanoplastics from clumps of oligomers.

19th February 2024

Innovation in Textiles

|

Switzerland

Plastic household items and clothing made of synthetic fibres release microplastics and those less than five millimetres in size can enter the environment unnoticed. A small proportion of these particles are so small that they are measured in nanometres and are the subject of intensive research because they can be absorbed into the human body. As of today, however, little is known about their potential toxicity.

Swiss researchers from Bernd Nowack’s group at Empa’s Technology and Society laboratory have now joined forces with colleagues from China to take a closer look at such nanoparticles released from textiles.

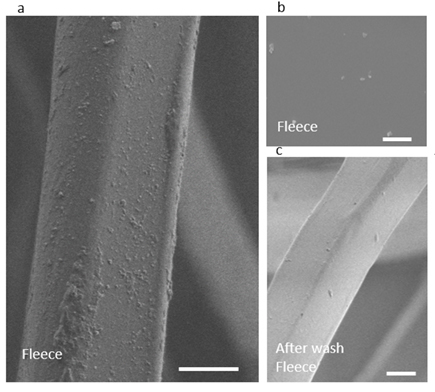

In earlier studies, Empa researchers were already able to demonstrate that both micro and nanoplastics are released when polyester is washed but a detailed examination of the nanoparticles has now shown that not everything that appears to be nanoplastic at first glance actually is.

Oligomers

To a considerable extent, the released particles were so-called oligomers – small to medium-sized molecules that represent an intermediate stage between the long-chained polymers and their individual building blocks, the monomers. These molecules are even smaller than nanoplastic particles and hardly anything is known about their toxicity either.

The researchers published their findings in the journal Nature Water. Twelve different polyester fabrics were washed up to four times and the nanoparticles released in the process were analyzed and characterised, which was not an easy task.

“Plastics, especially nanoplastics, are everywhere, including on our devices and utensils,” says Bernd Nowack. “When measuring nanoplastics, we have to take this ‘background noise’ into account.”

The researchers used an ethanol bath to distinguish nanoplastics from clumps of oligomers. Plastic pieces, no matter how small, do not dissolve in ethanol, but aggregations of oligomers do. The result was that around a third to almost 90% of the nanoparticles released during washing could be dissolved in ethanol.

“With other plastics, studies have already shown that nanoparticulate oligomers are more toxic than nanoplastics,” says Nowack. “This is an indication that this should be investigated more closely.”

The researchers were able to establish that the nature of the textile and the cutting method – scissors or laser – have no major influence on the quantity of particles released.

Repeated washes

The mechanism of release has not yet been clarified for nanoplastics or for the oligomer particles but the good news is that the amount of particles released decreases significantly with repeated washes. It is conceivable that the oligomer particles are created during the manufacturing of the textile or split off from the fibres through chemical processes during storage. Further studies are also required in this area.

Nowack and his team are focusing on larger particles for the time being. In their next project, they want to investigate which fibres are released during the washing of textiles made from renewable raw materials and whether these could be harmful to the environment and health.

“Semi-synthetic textiles such as viscose or lyocell are being touted as a replacement for polyester but we don’t yet know whether they are really better when it comes to releasing fibres,” Nowack concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more