Performance Days goes digital

Infrastructural leak detection and enhanced visibility in PPE.

29th July 2024

Innovation in Textiles

|

St Just Malmont, France

EweaveLab, which is headquartered in St Just Malmont, France, with its R&D lab located in nearby Sillingy, provides functional fabrics for a wide range of industrial sectors and is the developer of a smart textile solution designed to check the watertightness of structures.

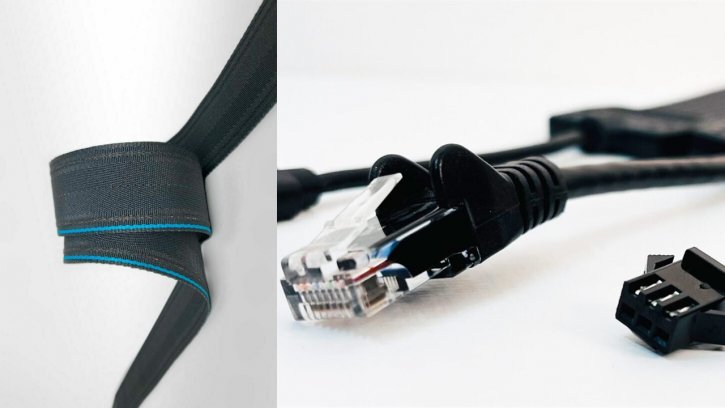

This comprises three elements – a linear sensor, a signal processing unit and a control interface hosted in the cloud.

It is being used to detect, locate and limit leaks in water networks and thanks to the physical characteristics of the linear sensor, is flexible, light, robust and easy to use, enabling pipes, for example, to be controlled and monitored instantaneously. It can be installed on any type of structure over a distance of up to a kilometre.

The cloud-enabled MyEweave control interface enables real-time monitoring 24/7 and the system can detect even the smallest volume of water – just a few drops are enough to trigger an alarm. Once dry again, the linear sensor can be put back into service. It will work for five years without recharging and provide feedback every five minutes and/or every 300 alarms triggered.

Multizone vest

At Techtextil 2024 in Frankfurt, the company also demonstrated a prototype multizone lighting vest designed to provide customisable visibility along with bluetooth and wifi connectivity.

The PPE vest is fully washable and repairable and features seven individually controllable lighting zones and a tactile control button. As such, it demonstrates another application for the company’s smart textiles which can also be engineered for temperature, tension and humidity detection, or actuation and activation via haptics, electrostimulation etc.

EweaveLab as a brand is now backed by AQ-Tech, a team of multi-disciplinary engineers dedicated to design and prototyping based in Annecy, and narrow fabrics manufacturer Satab.

Satab, based in Haute-Loire, has been weaving, braiding and knitting ribbons, braids, straps and cords since 1905 and has a weekly production capacity of of over ten million running metres.

As a European benchmark in the narrow fabrics industry, Satab combines the latest automated looms with the world’s largest active workshop of wooden shuttle looms, with a stock of over 40,000 reference designs amassed over many decades.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more