New dyes for high wet-fast colour in sportswear

Stretching produces distinctly measurable fluctuations in the yarn sensor’s charge

24th March 2023

Innovation in Textiles

|

Zürich, Switzerland

Researchers at ETH Zurich have developed an electronic yarn capable of precisely measuring how the body moves. Integrated directly into sportswear or work clothing, it can predict the wearer’s exhaustion level during physical exertion.

To test the new sensor, the researchers, led by Carlo Menon, Professor of Mobile Health Technology, integrated it into a pair of athletic leggings. Simply by glancing at their smartphone, testers were able to see when they were reaching their limit and if they ought to take a break.

The invention, for which ETH Zurich has filed a patent, could pave the way for a new generation of smart clothing since many of the products currently on the market have electronic components such as sensors, batteries or chips retrofitted to them. In addition to pushing up prices, this makes them difficult to manufacture and maintain.

In contrast, the ETH stretchable sensor can be integrated directly into the material fibres of stretchy, close-fitting sportswear or work clothing to make large-scale production both easier and cheaper.

“Since the sensor is located so close to the body, we can capture body movements very precisely without the wearer even noticing,” says Menon. “When people get tired and move differently – when running strides shorten and become less regular and our yarn sensor can measure this effect.”

Electric field

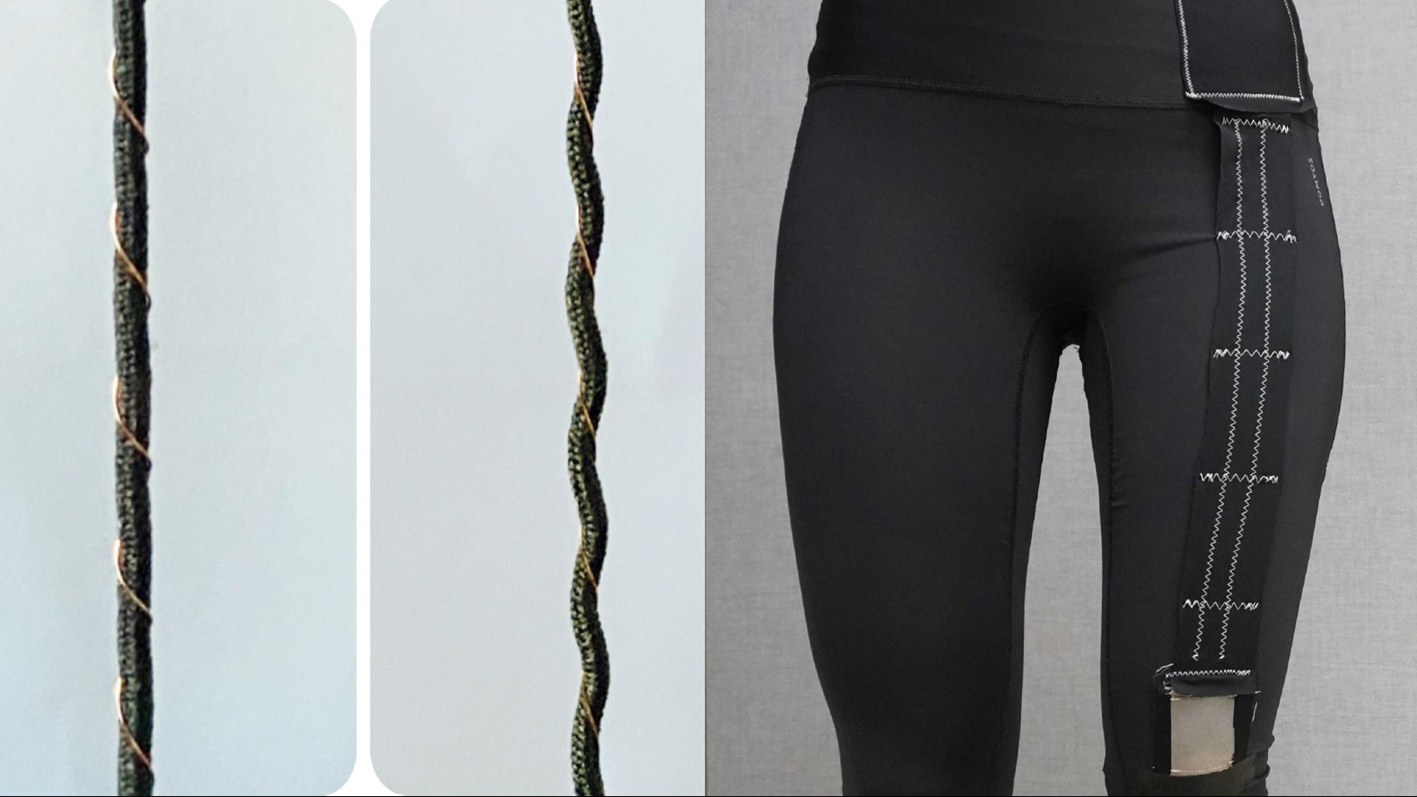

The yarn consists of inner fibre made of a conductive, elastic rubber wrapped in a rigid wire and clad in a thin layer of plastic.

“These two fibres act as electrodes and create an electric field, forming a capacitor that can hold an electric charge,” says Tyler Cuthbert, a postdoc in Menon’s group, who was instrumental in the research and development that led to the invention.

Stitching this yarn into the thigh section of a pair of stretchy running leggings means that it will stretch and slacken at a certain rhythm as the wearer runs. Each movement alters the gap between the two fibres, and thus also the electric field and the capacitor’s charge.

Under normal circumstances, these charge fluctuations would be much too small to help measure the body’s movements.

“Unlike most other materials, ours actually becomes thicker when stretched,” Cuthbert says. “As a result, the yarn is considerably more sensitive to minimal movements. Stretching it even a little produces distinctly measurable fluctuations in the sensor’s charge. This makes it possible to measure and analyse even subtle changes in running form.”

In previous research, Cuthbert and Menon observed a series of testers, who ran while wearing athletic leggings equipped with a similar sensor. They recorded how the electric signals changed as the runners became more tired. Their next step was to turn this pattern into a model capable of predicting a runner’s exhaustion which can now be used for the new sensor. Ensuring the model can make accurate predictions outside the lab, however, will require a lot of additional tests and masses of gait pattern data.

To enable the textile sensor to send electrical signals wirelessly to a smartphone, the researchers equipped it with a loop antenna made of conducting yarn, which was also sewn directly onto the leggings.

Together, the sensor and antenna form an electrical circuit that is fully integrated into the item of clothing.

The electrical signal travels from the stretchable sensor to the antenna which transmits it at a certain frequency capable of being read by a smartphone. The wearer runs and the sensor moves, creating a signal pattern with a continuously fluctuating frequency, which a smartphone app then records and evaluates in real time.

The researchers still have quite a bit of development work to do to make this happen but are working on turning their prototype into a market-ready product.

“Our goal is to make the manufacture of smart clothing cost-effective and available to the broader public,” Menon says. “I see the potential applications stretching beyond sport to the workplace – to prevent exhaustion-related injuries – as well as to rehabilitation medicine.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more