Shein partners with Transfar Chemicals

Annabella Ng, Shein’s senior director of public affairs, outlines how the brand has pioneered a highly successful and game changing supply-chain-wide business approach.

27th February 2025

Innovation in Textiles

|

Singapore

Innovation in Textiles (IiT): Shein has developed its own proprietary supply chain management software to oversee its vast network of suppliers, production processes and logistics. Can you tell us a little more about its components and how they all fit together?

Annabella Ng (AN): Unlike the traditional supply-driven model, Shein’s small-batch on-demand business model is powered by a highly integrated digitalized system that enables us to respond to the needs and preferences of our customers with a high level of precision and agility.

It starts with the ability to measure demand signals accurately – from the way our customers engage with our app or website through clicks and likes, to actual sales of products. This provides real-time insights into popular styles that our customers want, and whether these are ‘basics’ that are popular all year round or centred around a season or occasion. These insights are also accessible by Shein supplier partners through our proprietary supplier management platform, providing them with better visibility into customer demand, so that they can plan and make more accurate manufacturing decisions.

Overall, this enables Shein’s supply chain to be highly accurate in producing based on actual demand and in turn, helps us to minimise production waste from the start and maintain consistently low unsold inventory rates of around single digit percentages – far below the industry average.

Another key element to Shein’s business model is our “test-and-learn” approach, which involves testing new products in small initial batches of 100-200 items and monitoring customer interest and demand before scaling up the production for popular styles. This gives us the agility and speed to adjust our production to respond to emerging trends quickly.

Finally, by operating an online-only retail model, we are able to reduce overhead costs associated with running brick-and-mortar stores, so we are able to make our products available to customers across 150 countries globally, as long as local delivery can be supported.

By leveraging technology and digital tools to transform the traditional fashion production model, Shein is able to save costs at various layers of the business, which we pass on to our customers through lower prices without compromising on the range and diversity of styles and sizes offered. At the end of the day, we hope to empower every Shein customer, no matter their geographic location, income, size, body shape or style preference, to express their individuality through fashion.

IIT: Can you outline some of the new technologies you've been encouraging your suppliers to adopt?

AN: At Shein, we invest in research and development (R&D) of advanced manufacturing technology and production processes that have the potential to drive greater efficiencies in our supply chain. In 2022, we established the Center of Innovation for Garment Manufacturing (CIGM) in Guangzhou, China, to conduct R&D in waste-saving and efficiency-optimizing technologies and techniques, and to share these with our suppliers. In 2023, the CIGM conducted over 380 training sessions for more than 5,000 suppliers and has also developed over 100 sewing and garment-making tools such as those to simplify complex craftsmanship methods.

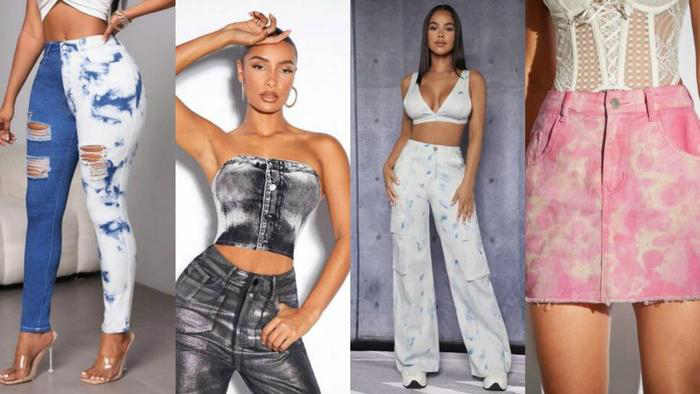

Digital Thermal Transfer Printing and Cool Denim Transfer Printing are two examples of technologies that we have found to be highly efficient in reducing water consumption compared to traditional printing methods. These have been independently verified in separate studies conducted by Bureau Veritas. Given that the significant water savings generated from the use of these technologies have environmental benefits and will also help our suppliers to reduce their costs of operation, we have encouraged and supported our suppliers in adopting these technologies.

Digital Thermal Transfer Printing is waterless method of printing designs onto thermal transfer paper before using a heat-activated process to transfer the patterns onto the fabric. Since the start of this initiative in December 2018, over 65% of our directly sourced prints are produced use Digital Thermal Transfer Printing.

Cool Denim Transfer Printing also uses less water and energy compared to conventional denim washing processes. Most denim garments start off with pre-dyed denim fabric which is cut into patterns before being sewn together. Denim wash effects such as whiskering or stone washing are then applied to the assembled denim garments.

Using the Cool Denim Transfer Printing process, denim patterns and denim wash effects are printed on transfer film as part of a single design and imprinted onto white denim fabric. The patterns are then cut from the fabric and assembled. This process reduces the use of harsh chemicals and requires 70.5% less water than convention denim washing methods and is a more efficient way to create trending denim styles without compromising on quality.

IIT: You are also developing a new polyester recycling method with Donghua University, can you tell us how this works primarily, and what your expectations are for it going forward?

AN: The process we have developed in partnership with Donghua University combines mechanical and chemical recycling processes and allows for a broader range of pre- and post-consumer polyester waste feedstock including both textiles and polyethylene terephthalate (PET) bottles. The resulting fibres from the process can also be recycled multiple times without significant degradation of key material properties, according to tests conducted by the project team.

Polyester accounts for the majority of Shein’s fibre portfolio, which makes the transition to recycled polyester a vital part of our evoluShein strategy. We aim to transition at least 31% of the polyester used for Shein-branded products to recycled polyester by 2030.

At this stage of the project, Shein’s focus is on working with the Donghua University research team and a selected group of fibre manufacturing partners to migrate the polyester recycling processes from a lab-setting to a larger-scale commercial production facility. The team at Shein sees significant potential in this technology to offer improved cost efficiencies compared to existing recycled polyester options used in Shein’s products, with improved recyclability, and we are working to ensure the process is scalable and reliable. We know there is a high level of interest in this project, and we will keep everyone informed on our progress and share updates as they become available.

IIT: What are the main benefits of working with Shein for suppliers?

AN: At Shein, we focus on building long-term relationships with our suppliers who are predominantly small and medium-sized businesses. We believe in empowering our suppliers with the right tools, knowledge and capabilities they need to adapt to changes in the industry, so that they can grow along with us.

We invest significantly in helping our suppliers learn how to leverage our digitalized supply chain and use the demand insights to be more efficient and accurate in their production. We also conduct separate training sessions for our suppliers, which cover topics such as best practices in business and operational processes, the latest manufacturing technologies and techniques, and quality inspections and assurance. Shein also works to ensure that we pay all our suppliers quickly – all within 30 days, and some even on a weekly or bi-weekly basis – compared with an industry average of around 90 days. We also enable centralised purchasing of materials by negotiating lower prices with the fabric manufacturers with our scale, helping our Tier 1 contract manufacturers to reduce their costs of materials.

Besides forming strong relationships with our suppliers, we also believe in supporting their workers, as part of our efforts to improve lives across communities that we operate in. Our Supplier Community Empowerment Program provides financial support for suppliers to upgrade, expand and enhance spaces in their facilities such as canteens, dormitories, and childcare centres, so that their employees can work in more conducive environments. Suppliers’ employees that require financial assistance, for instance with school fees for their children or medical bills due to serious illnesses, may also apply for grants through Shein’s Spotlight programme. Since the inception of the programme through to 2023, we have disbursed over US$460,000 in grants to support 385 families.

IIT: How are you addressing the need for transparency in supply chains which will be important in the next few years?

AN: Transparency is a critical factor in building trust with our customers, partners and stakeholders. As we continue to evolve, we are committed to increasing visibility into our supply chain governance policies, enforcement mechanisms, operations and sharing transparently on incidents uncovered and any mitigating actions taken by Shein.

Key policy documents that our suppliers must agree to abide by are published on the Shein corporate website. These include for instance, our Supplier Code of Conduct (SCoC), Shein Responsible Sourcing Policy which provides information on how we categorise and take action against violations of our SCoC, as well as a Restricted Substances List which governs our chemical safety requirements on products procured.

We also disclose key statistics regarding oversight of our supply chain on a voluntary basis through our annual Sustainability and Social Impact Report. For instance, the number of unscheduled audits conducted by independent third-party verification agencies into our suppliers, as well as the results of these audits, data on egregious violations found such as child labour cases, and actions taken by Shein against violating suppliers, including the number of suppliers terminated in a given year.

We are also taking steps to expand the depth of our reporting, by studying international sustainability reporting standards such as the Global Reporting Initiative (GRI), which we current report against, and increasing the number of disclosures in our reports that have undergone external third-party limited assurance. Additionally, we engage with industry experts, advocacy groups, and regulatory bodies to ensure that we continue to work on our supply chain governance programs and align them with global industry expectations.

We understand that supply chain transparency is an ongoing journey, and we are committed to continuous improvement by enhancing our governance and supplier engagement programs.

IIT: What are the company’s key goals and expectations in 2025?

AN: At Shein, we are committed to enhancing our governance programme and oversight and continuing to make progress across all three pillars of our evoluShein strategy.

On the People pillar where we are committed to the equitable empowerment of communities, we announced in January the establishment of the Shein Foundation, a non-profit organisation that will be the philanthropic arm of Shein, along with our first grant to the Africa Collects Textiles Foundation, to promote used textiles donations and recycling in Kenya and the African region. We look forward to consolidating more of our social impact activities under Shein Foundation in the coming year, to advance its mission to build more inclusive communities and sustainable ecosystems.

Under the Planet pillar, we remain focused on implementing and scaling our decarbonisation measures, particularly our Scope 3 emissions. While this is a huge challenge for all industry players, Shein has the additional complexity of tackling this while we are still in a growth stage compared to more mature businesses. Nonetheless, we are starting to put in place key foundational strategies that we hope to scale across our operations in the coming years.

Finally, on the Process pillar, we remain committed to reducing waste and increasing circularity through innovation. Our investment into recycled polyester technology is one such example, and we look forward to announcing more initiatives in the year ahead.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more