Color Atlas from Archroma and Datacolor

How new technology is streamlining the colour approval process for some of the world’s largest clothing manufacturers and their customers.

6th March 2025

Innovation in Textiles

|

United Kingdom

Russell Thorpe, colour management consultant and DigiEye applications specialist at UK-headquartered VeriVide talks to Innovation in Textiles...

Colour accuracy is crucial across many industries, but given the environmental impact of the clothing sector, ensuring colour consistency across textile batches – and having the ability to remotely approve and make sustainable colour decisions – will have a hugely positive effect on the carbon footprint of the textile industry in the coming years.

There have been significant technological developments in the shift from analog to digital workflows, driven by the products and systems developed by VeriVide, and these go hand in hand with the growing awareness and transition towards more sustainable workflows.

As the industry continues to evolve – often producing quicker turnarounds and cheaper products – VeriVide technology ensures consistency of colour without the need to ship large numbers of physical samples.

Compliance

Brands have always conducted compliance audits but these now include actual process and product sustainability metrics. Most retailers and brands generally report quarterly sustainability figures, aiming to reduce their carbon footprint and gather data from the supply chain to inform their approach. Factories are now being invited to become greener and more ethical by ensuring workforce diversity and fair wages etc., as well as investing in eco-friendly measures such as solar panels and wastewater recycling.

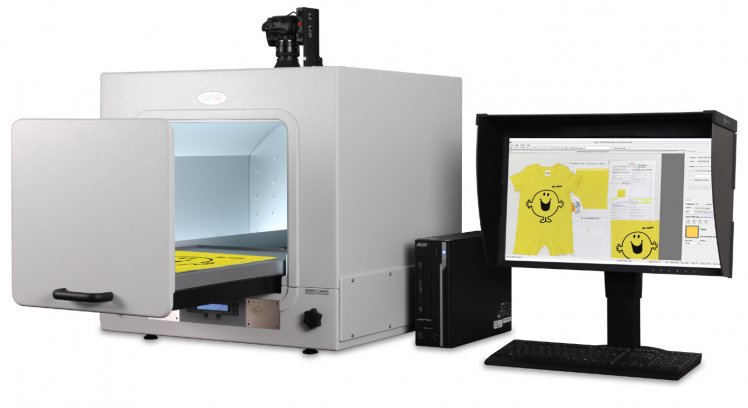

Investing in additional systems like the DigiEye calibrated digital image capture system makes the colour approval process quicker and more efficient.

The textiles sector is the most advanced in using colour measurement equipment because colour is vital in fashion. To successfully sell product, you need to get the colours right. Fifty years ago, most retailers or brands probably had two seasons – winter and summer. Nowadays, they have at four seasons a year, with options to phase in new products when necessary. Suppliers can now offer a fast-track colour service using digital technology, and this is becoming the standard approach to visualising and approving colours remotely.

Having a digital approach has made the industry more flexible in terms of speed to market, which is incredibly important in textile retail. If you don’t have the right colour at the right time, that style won’t sell.

Variations

Historically, the textile industry used dyed pieces of fabric or painted cardboard to convey the desired colour, matching these standards against the material in question. The digital world then began to infiltrate with the introduction of spectrophotometers, which measured the light reflected off textiles or materials to provide the necessary data to determine whether a textile colour is correct or not. However, spectrophotometers have some limitations since not every device is the same, and data measured from black and dark materials can be particularly challenging.

The spectrophotometers may provide similar results, but there can still be significant variation in how the colour looks compared to instrumental measurement. This applies even to batches of the same item produced in different factories using the same dye recipe. In the textile industry, this can be a major issue, particularly when restocking, as items intended to match can appear different to the human eye.

More than numbers

Spectrophotometers can measure colour to two decimal places, providing measured reflectance data, but at VeriVide, we believe that colour is more than just numbers. You really need to visualise the colour to check whether it falls within the tolerance range. For example, if the pass/fail tolerance is Delta E 1.0 and you have production in China telling you it’s Delta E 1.3, this would typically be a cause for rejection, but do you really need to reject it?

Do you send that batch of fabric back into the dyeing machine for another 10 hours? Think of all the energy, steam, water, chemicals, and wastewater being used to achieve a slight improvement in shade. Redyeing means the fabric is subject to more mechanical rotation within the dyeing machine, so after another 10 hours of processing, the fabric becomes worn, automatically becoming second quality. So, you’ve just created second-quality material because of a small difference in a pass/fail number.

What we can now do with a digital workflow is to submit a calibrated image of the sample to the customer for commercial review. This can be viewed and assessed on a screen and given much fairer consideration—i.e., accept what you have. It’s a more sustainable approach. You’re not wasting product, and it gives you the option to make a second decision instead of rejecting it.

Organic cotton

Most brands and retailers are pursuing a more sustainable approach, especially regarding cotton. Organic cotton or cotton grown using better methods is the answer. However organic cotton has more natural variation since it is not forced grown using pesticides and fertilisers (as these are not harming the soil and environment). You will see colour variations of ecru undyed cotton from season to season, and fabric buyers need to understand that organic cotton will exhibit more variation. We don’t want to chemically pre-treat the fabric being dyed if there’s a little more variation in the natural colour. Some mills use enzymes before bleaching and dyeing to reduce the variation, but this undermines the organic nature of the fabric.

So, you’re processing a natural product with more variation due to the way it’s grown but then trying to eliminate the variation with additional chemical processes. If it’s organic, we should keep it organic. Hopefully brands are becoming more aware that they may need a slightly larger colour tolerance to keep the process robust, commercially viable and sustainable.

It is widely recognised that consumers want to know the origins of the products they buy. They want assurance that items are produced sustainably, not in sweatshops, for instance. Essentially, consumers want to know that products are manufactured in a way that avoids polluting the environment.

Global profiles

The lab dyeing process is a lengthy one and each lab dye round can take one or two days. These lab dips are then submitted to the brand or retailer for approval. Once approved, orders can be processed. Mills and Factories with approved colours receive the first choice of production runs, so it’s in their best interest to get colours approved as quickly as possible to become preferred suppliers.

They can use the DigiEye System to speed up this process. Once bulk orders are placed, the same factory that produced the lab dye will fulfil the bulk fabric order. If, for instance, a fabric batch produces 2,000 units of small, 2,000 units of medium, and 2,000 units of large, and the medium size sells out in the store, you need to replace that with an identical colour. What you don’t want is a rack of garments where the medium size is a different colour.

Instead of sending a physical lab dye sample, which can take a week or more to reach the owner’s desk, you can now do this digitally and get the samples within minutes of it being sent. Once digitised, it needs to be visualised on screen. This is where the trusted Eizo calibrated monitors comes into play.

Eizo is integral to our business, and our customers expect to see an Eizo product, particularly within the new VisionView – VeriVide’s tunable, all-LED light booth with Eizo display for colour assessment. We can trust the digital twin technologies because the digital twin image contains all the colour information. You can open the image, supplied as an RGB TIFF on the monitor, and it will use the system’s embedded calibration profile. So, even if the DigiEye imaging system is in Bangladesh, it will use that profile and create an accurate duplicate of the monitor image for immediate colour assessment.

Vision-based remote colour assessment displays the actual product colour, not just numbers on a screen. Our new DigiView software allows users to create a swatch and move it next to or overlap the batch on the screen to perform a visual colour comparison. When placed over the batch and when the standard swatch disappears, it means the colours are very close or indeed identical. If it looks slightly darker or more blue – for example, then it is. It’s as simple as that, and it has made the system so user-friendly. If you’re buying bottoms from Turkey and the tops from China, you can now compare them together on-screen and, if they look the same, then there’s no cause for concern. This is crucial for colour continuity in retail.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more