Robotic assistance for Ugurlular Tekstil

Installation includes fully automated ROBOspin piecing robot and SERVOtrail roving bobbin transport system.

21st October 2024

Innovation in Textiles

|

Italy

Beste, headquartered in Prato, Italy, has ordered a complete Rieter ring spinning system along with digitization and automation solutions to equip its new Filum mill located in Bergamo.

The investment is a key component of the ITACO project which is focused on creating a 100% organic and fully traceable Italian cotton supply chain – from the cultivation of organic cotton in southern Italy to spinning in Bergamo and garment manufacturing in the Prato region.

The goal is to produce materials of the highest quality for luxury brands within a supply chain spanning just a few hundred kilometres, in order to provide unparalleled control.

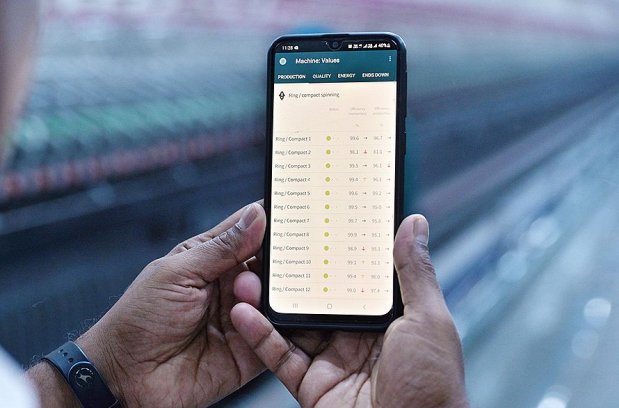

The new spinning mill will be exclusively equipped fully electronic G 38 ring spinning machine with a COMPACTapron compacting device and controlled by the all-in-one Essential digital mill management system providing a comprehensive view of all relevant performance indicators from bale to package.

A fully automated ROBOspin piecing robot and SERVOtrail roving bobbin transport system will further ensure consistent performance and minimise personnel deployment.

“We engage with partners who share our philosophy and standards,” says Giovanni Santi, CEO of Beste. “Rieter machines meet our demand for the highest quality and enable us to produce yarns for our garments that embody the design and quality hallmarks of ITACO, our unique, fully traceable Italian cotton project.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more