Hohenstein presents Spacetex update

On 28 May 2014, the German ESA astronaut Dr Alexander Gerst will take off from the cosmodrome in Baikonur, in Kazakhstan, bound for the International Space Station (ISS). During the six-month Blue Dot mission, Dr Gerst will be responsible for almost 40 different experiments including the Spacetex project, the first clothing physiology experiments to be carried out in a weightless environment.

18th April 2014

Innovation in Textiles

|

Boennigheim

On 28 May 2014, the German ESA astronaut Dr Alexander Gerst will take off from the cosmodrome in Baikonur, in Kazakhstan, bound for the International Space Station (ISS).

During the six-month Blue Dot mission, Dr Gerst will be responsible for almost 40 different experiments including the Spacetex project, the first clothing physiology experiments to be carried out in a weightless environment.

The Spacetex research partners from the Hohenstein Institute, Schoeller Textil, Charité and DLR are expecting unique results from the joint project. It is hoped that the tests deliver essential information for developing new textile products for use in extreme climatic and physiological conditions on Earth.

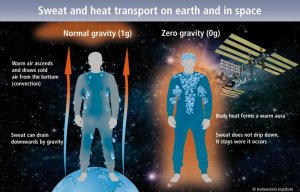

Project leader Dr Jan Beringer of the Hohenstein Institute commented: “Among other things, the lack of gravity affects the way body heat and sweat are transported through clothing that is worn next to the skin. To ensure that the body's cooling mechanism is still properly maintained, textiles have to be specially adapted for use in space.”

Industrial researcher Dr Beringer, who is listed as the project’s Principal Investigator (PI), believes performance-based textile functions, such as antimicrobial textile finishes, will be key in future developments.

At the end of February, Dr Jan Beringer and Prof Dr Hanns-Christian Gunga of the Center of Space Medicine at the Charité in Berlin, attended Dr Alexander Gerst's training for the project at the European Astronaut Centre (EAC) in Cologne.

In preparation for his duties while in orbit, Dr Gerst performed four intensive treadmill workouts on four separate days during his preflight training. During two of the training sessions, he wore functional underwear made of special polyester.

In zero gravity, the breakdown of muscle and bone tissue begins very quickly. During that process, the body gives off heat just as it does on Earth, and tries to cool itself down by releasing and evaporating sweat. However, in the space the heat envelops the body almost like an aura. This means the cooling effect on the body is lost and the training imparts greater physiological strain than it does on Earth.

“We will feed the findings from the Spacetex project into our product development and optimisation work, said Hans- Jürgen Hübner, Schoeller Textil AG. “We’ll also make sure that people here on Earth who push the limits of their physical endurance or have to deliver peak performance in extreme conditions benefit as well. That includes, of course, athletes of all kinds but also firefighters, catastrophe relief workers and members of the armed forces.”

The functional and cotton textiles were subjected to an extensive series of tests on the Hohenstein skin model that simulates the thermoregulatory system of human skin. Various clothing physiology parameters such as water vapour resistance, which indicates breathability, and thermal insulation were measured in standardised climatic conditions and normal gravity.

In order to be able to take comparative measurements in micro-gravity, the Hohenstein Institute is developing a special version of the Hohenstein skin model that could possibly be expected to be used in 2016 on board an Airbus A300 during the parabolic flights.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more