Major gains with centrifugal multispinning

Research paves the way for the less wasteful and more effective application of antibiotics.

30th March 2022

Innovation in Textiles

|

Switzerland

Empa researchers in Switzerland are working on polymer fibres that soften as soon as the environment heats up due to an infection, triggering the release of antimicrobial drugs. A bandage that releases medication as soon as an infection starts in a wound could treat injuries more efficiently.

At present, it is not possible to tell from the outside whether a wound will heal without problems under a dressing or whether bacteria will penetrate the injured tissue and ignite an inflammation. To be on the safe side, disinfectant ointments or antibiotics are applied to the wound before the dressing is applied. However, these preventive measures are not necessary in every case and as a result, medications are wasted and wounds over-treated.

The wasteful use of antibiotics also promotes the emergence of multi-resistant germs, which are an immense problem in global healthcare.

Researchers at Empa’s Biointerfaces and Biomimetic Membranes and Textiles laboratories in St Gallen want to change this.

The idea of the interdisciplinary team led by Qun Ren and Fei Pan is that the dressing should be loaded with drugs and react to environmental stimuli so that wounds could be treated as needed at exactly the right moment.

As an environmental stimulus, the team chose a well-known effect – the rise in temperature in an infected, inflamed wound.

To design a material that would react appropriately to this increase in temperature, the team developed a skin-compatible polymer composite made of several components – acrylic glass (polymethyl methacrylate, or PMMA), which is used, for example, for eyeglass lenses and in the textile industry, and Eudragit, a biocompatible polymer mixture that is used to coat pills.

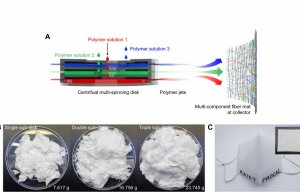

Electrospinning was used to process the polymer mixture into a fine membrane of nanofibres. Octenidine was then encapsulated in the nanofibres as a medically active component. Octenidine is a disinfectant that acts quickly against bacteria, fungi and some viruses. In healthcare, it can be used on the skin, on mucous membranes and for wound disinfection.

Signs of inflammation

Greek physician Galen described the signs of inflammation back in the 1st century and his five Latin terms are still valid today – dolor (pain), calor (heat), rubor (redness), tumor (swelling) and functio laesa (impaired function).

In an infected skin wound, local warmth can be as high as five degrees. This temperature difference can be used as a trigger because suitable materials change their consistency in this range and can release therapeutic substances.

“In order for the membrane to act as a smart bandage and actually release the disinfectant when the wound heats up due to an infection, we put together the polymer mixture of PMMA and Eudragit in such a way that we could adjust the glass transition temperature accordingly,” explained Fei Pan. “This is the temperature, at which a polymer changes from a solid consistency to a rubbery, toughened state. Figuratively, the effect is often described in reverse – if you put a rubber glove in liquid nitrogen at –196 degrees, it changes its consistency and becomes so hard that you can shatter it like glass with one blow.”

The desired glass transition temperature of the team’s polymer membrane was in the range of 37 degrees. When inflammation kicks in and the skin heats up above its normal temperature of 32 to 34 degrees, the polymer changes from its solid to a softer state. In laboratory experiments, the team observed the disinfectant being released from the polymer at 37 degrees – but not at 32 degrees.

Another advantage is that the process is reversible and can be repeated up to five times, as it switches itself off when it cools down.

Following promising initial tests, the Empa researchers now want to fine-tune the effect.

Smart and unsparing

To investigate the efficacy of the nanofibre membranes against wound germs, further laboratory experiments are now in the pipeline. Qun Ren has long been concerned with germs that nestle in the interface between surfaces and the environment, such as on a skin wound.

“In this biological setting – a kind of no man’s land between the body and the dressing material – bacteria find a perfect biological niche,” he explained.

Infectious agents such as staphylococci or Pseudomonas bacteria can cause severe wound healing disorders. The team consequently allowed these wound germs to become acquainted with the smart dressing in a Petri dish with positive results – the number of bacteria was reduced roughly 1,000-fold when octenidine was released from the smart dressing.

“With octenidine, we have achieved a proof of principle for controlled drug release by an external stimulus,” said Qun Ren. “In future the technology could be applied to other types of drugs, increasing the efficiency and precision in their dosage.”

Smart dressings

Empa researchers are working in interdisciplinary teams on various approaches to improve medical wound treatment. Liquid sensors on the outside of the dressing, for example, make it visible when a wound is healing poorly by changing their colour. Critical glucose and pH values serve as biomarkers.

To enable bacterial infections to be contained directly in the wound, the researchers are also working on a polymer foam loaded with anti-inflammatory substances and on a skin-friendly membrane made of plant material. The cellulose membrane is equipped with antimicrobial protein elements and kills bacteria extremely efficiently in laboratory tests.

Digitalisation can also achieve more economical and efficient dosages in wound care and Empa researchers are developing digital twins of the skin that allow control and prediction of the course of a therapy using real-time modelling.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more