Rethinking civil engineering at ITM

Max Glass Eco brings new flexibility in the high speed production of composite reinforcements for the wind industry.

20th June 2024

Innovation in Textiles

|

Chemnitz, Germany

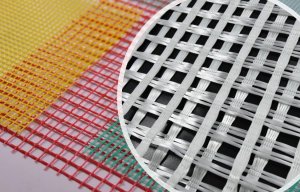

Karl Mayer Technical Textiles, based in Chemnitz, Germany, reports significant interest in its new and highly economical Max Glass Eco machine for the production of standard non-crimp fabrics made of glass fibres for composites.

The Max Glass Eco is aimed primarily at the production of wind blades and was introduced at this year’s JEC World show in Paris, and at the later Techtextil in Frankfurt.

It incorporates proven solutions from the Karl Mayer Group’s range of multiaxial machines, including features from its predecessor, the Maxtronic, combined with sophisticated new technical developments.

It is available with a working width of 2.5 metres and suitable for laying angles of +/-45°, with a rotational speed of 1,800 revolutions per minute for a maximum output of 410 metres per hour.

A complementary layering system ensures a uniform take-up speed and gentle processing of the fibre. This sophisticated weft tension compensation device is one of the tried and tested features of Karl Mayer multiaxial technology that have been integrated into the new machine. Others include the fibre chopping unit, which allows glass fibre chips to be introduced into the laying process and thus cover more fields of application, and a single pin transport chain for reduced waste.

A new fixed layer system ensures extremely high placement precision at all laying angles and the walking needle system prevents the formation of lanes even with long stitch lengths. The fitted single compound needles can be changed efficiently.

“Customers have bee particularly impressed by the short pay back times with the new Max Glass Eco,” says the company’s sales manager Ralf Schramm. “The high performance of the machine is combined with an extremely attractive price and we had many customers at a presentation of it at our development centre in Germany in April. For Asian customers, a Max Glass Eco is available for performance demonstrations at Karl Mayer China in Changzhou.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more